عنا

مرحبا هل يمكنني مساعدتك؟

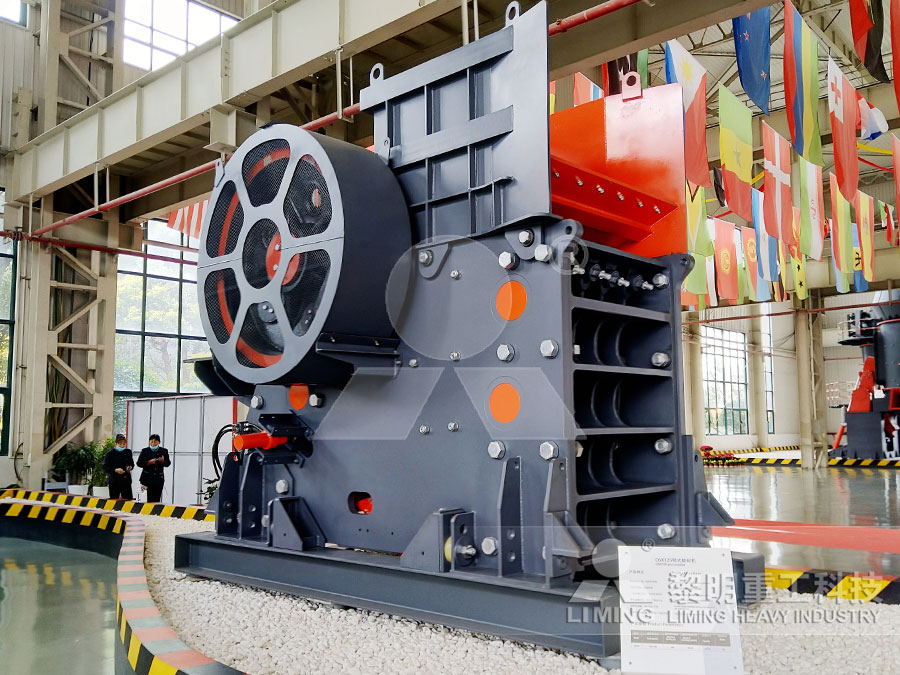

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

crushing plant designing

2020-01-19T12:01:32+00:00

The Ultimate Guide to Designing an Efficient

2023年2月23日 This comprehensive guide provides valuable insights into the design and construction of an efficient aggregate crushing plant From selecting the right equipment to optimizing the layout and process flow, 2020年12月2日 The sand aggregate production line can be simply summarized as crushing, screening, and storage In order to obtain How to Design a Crushing Plant Imagup2023年2月28日 Discover the best practices for designing a successful stone crusher plant, including factors to consider, equipment selection and configuration, environmental management, and safety and maintenance Stone Crusher Plant Design: Best Practices for

Mineral Processing Plant Design University of

2018年1月19日 to the SAG mill In other words, crushing plants, from primary to quaternary circuits, are here to stay There are three main steps in designing a good crushing plant: 2018年10月19日 This document presents a proposal for designing an expert system in the Gabriela Mistral Division’s crushing plant belonging to Codelco (Chile) with the objective of maximizing stacked tonnage, Design and Evaluation of an Expert System in a 2014年8月21日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the Setting up of crushing plant: design and layout

Design and Evaluation of an Expert System in a Crushing

2019年5月27日 Abstract: This document presents a proposal for designing an expert system in the Gabriela Mistral Division’s crushing plant belonging to Codelco (Chile) with 2022年4月19日 The crusher plant design should consider the multistage crushing principle, normally it includes primary crushing, secondary crushing, tertiary crushing, Stone crusher plant design Henan Deya Machinery Co, Ltd2020年10月27日 More about this topic in part 2 of Design of Crushing and Screening plants: Secondary Stage From the basic design with a grizzly feeder and a jaw crusher Designing a Crushing Screening Plant – Part I Primary Jaw Crushing

Design of a crushing system that improves the crushing

2016年2月10日 up This paper addresses the critical design parameters that will increase the crushing capacity of the plant to 35 tonnes per hour There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The paper analyses all of these steps Keywords Gold mining, crushing, Zimbabwe, jaw 2012年10月15日 By L Winchip, engineering manager, and G Mangrich, regional sales manager, McLanahan Corp Several considerations need to be taken into account in designing an efficient crushing and screening Crushing and Screening AggNet2 天之前 We are committed to designing the best plant solutions for crushing, recycling and wastewater treatment Baioni is a world partner in the development, design and production of machinery BAIONI Baioni Crushing Plants – Crushing and Water

大豆压榨厂粉尘爆炸隐患及处理措施Hidden danger of dust

通过相关处理措施以最大限度地降低大豆压榨厂粉尘爆炸隐患,做到安全生产,保护员工和公司的财产。 The dusts in the soybean crushing plant are mainly organic dust, and the dusts are also divided into the soybean dust and containing hexane dust and the soybean meal dust The dust layer and the dust cloud 1 Considerations of stone crusher plant design The basic purpose of crushing ore is to achieve a certain particle size requirement for ore, raw materials or fuel In ore dressing, the purpose of crushing ore is: (1) supply the most reasonable ore feeding size for rod grinding, ball milling, or provide qualified grinding medium for autogenous Crushing Plant Design and Layout Considerations JXSC Mine2012年10月15日 The intention of this article is to provide an overview of matters to be considered when designing a crushing and screening plant, starting with a blank sheet – when planning a plant upgrade or extension, preexisting factors may overrule the ability to incorporate some or all of these considerations It is not intended to recommend specific Enhanced Plant Design for Aggregate Processing AggNet

Setting up of crushing plant: design and layout considerations

2014年8月21日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of parties These can include the owner’s 2015年10月15日 Steadystate modelling and simulation tools are widely used in designing of a new process for industrial coarse comminution circuit (crushing plant) (NapierMunn et al 1996;King 2001)(PDF) Crushing Plant Dynamics ResearchGate2017年3月4日 Today, stationary, semimobile and m obile crushing plants with capacities ranging from 500 to more than 10,000 t/h are used prov ing for crushing and processing hard roc k, limestone, coal,(PDF) SIZE REDUCTION BY CRUSHING METHODS

Minerals Free FullText Applied Calibration and Validation

2021年8月25日 This paper presents a method of integrating an experimental and datadriven approach for calibration and validation for crushing plant equipment and a process model Tuppurainen, D; Bearman, R Designing Comminution Circuits with a MultiObjective Evolutionary Algorithm In Proceedings of the 2005 IEEE Congress on 2023年1月17日 Crushing Plants Designing a crushing plant involves several key steps, including: Defining the purpose and output of the crushing plant This includes the type of material to be processed, the How to design a crushing plant? LinkedIn2018年1月19日 In other words, crushing plants, from primary to quaternary circuits, are here to stay There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational Mineral Processing Plant Design University of

Crushing Technologies thyssenkrupp Polysius

Mobile thyssenkrupp crushing plants are in operation all around the world Mobile crushing plants make it possible to crush minerals directly at the site of extraction and synchronize to the rate of mining advance, into sizes ready for conveyor transport of the crushed material from the mining face to the processing plant Find out more2021年10月21日 Muar Ban Lee Group is a worldleading palm kernel expeller manufacturer specializing in palm oil machinery and oil seed crushing machinery We provide "One Stop Service" in setting up Palm Kernel Crushing Plants from Plant Design and Fabrication to Installation and Commissionning With our indepth knowledge of the Malaysia Palm Kernel Expeller Mills Manufacturer MBL2017年5月30日 designing our products based on a needs analysis, often identifying vital factors that even the client wasn’t aware of This is the reason why Meka crushing and screening plants and concrete plants are preferred in regions with widely varying environmental and geographical conditions, such as England, Ecuador, Siberia, Chile, CRUSHING SCREENING Crushing and Screening

Improving yield and shape in a crushing plant ScienceDirect

2009年6月1日 The goal of crushing plants is the optimised production of certain sized rock fractions, and in some cases, the achievement of a certain level of product quality This article presents a novel mathematicalphysical model for designing and testing a ring armor for vertical shaft impact crusher (VSI) to reduce energy consumption, improve Since 1955 Senya Crushers has been manufacturing concrete crushing plants and equipment and designing mining and aggregate production lines Our product line includes MICRO Crushers, Jaw, Impact Cone Crushers, Portable Crushing Plants, Crawl Mobile Crushers, MICRO Conveyors, Radial Yard Conveyors and Transfer ConveyorsMicro Concrete Crushers Conveyors Portable Rock Crushing 2016年3月10日 Crushing Plant Flowsheet DesignLayout In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in size, but they work much more efficiently if their feed is ½ in or less Before the advent of the Symons cone Crushing Plant Flowsheet DesignLayout 911 Metallurgist

A Catalog of All Mobile Crushing Station Fote Machinery

2023年10月27日 The price of the mobile crushing plant is also customized according to demand and budget 1 Mobile Screening Station Highperformance mobile screening plants can realize multistage screening Length: 11,00012,500 mm Width: 3,8004,000 mm Height: 3,8003,900 mm Weight: 2838 tMobile crushers are trackmounted rock crushing machines that are easily movable on and between production sites They are widely used in aggregates production, recycling applications, and in mining operations Mobile crushers can replace stationary crushing systems, which reduces the need for hauling and thus cuts operational costsMobile crushers 2023年9月23日 Tradeoff curves between various performance indicators of the crushing plant using a dynamic simulation platform are generated using multiobjective optimization using a nongradientbased algorithm (genetic algorithm) Tuppurainen, D; Bearman, R Designing comminution circuits with a multiobjective evolutionary algorithm In TradeOff Curves for Performance Optimization in a Crushing Plant

Stone crusher plant design Henan Deya Machinery Co, Ltd

2022年4月19日 In the stone crusher plant processing, the appropriate stone crusher should be chosen based on the different raw materials First of all, when we categorize the raw materials, we can roughly divide the raw materials into hard stone and soft stone Hard stone typically includes cobblestone, granite, basalt, whose hardness is basically above 150Mpa2020年10月27日 Jaw crusher stage with a screen in the grizzly bypass to extract a 090 mm product Figure 5 Jaw crusher stage with a screen that process all material and allows for production of 030 mm, 060 mm or 0‑90 mm Figure 6 The rock size varies in the muck pile, as seen in the picture the number of large rocks is far greater on the right sideDesigning a Crushing Screening Plant – Part I Primary Jaw Crushing 2019年8月5日 The selection of an appropriate processing circuit for a specific material is one of the most important decisions in the design of a processing plant The importance is related to the fact that the capital and operating costs for the crushing/screening portion generally represent the major portion of the plant costsPQ University Lesson 2: Site Selection Plant Design

Crushing Plant an overview ScienceDirect Topics

A crushing plant delivered ore to a wet grinding mill for further size reduction The size of crushed ore (F 80) was 40 mm and the SG 28 t/m 3 The work index of the ore was determined as 122 kWh/t A wet ball mill 1 m × 1 m was chosen to grind the ore down to 200 μm A 30% pulp was made and charged to the mill, which was then rotated 2016年4月14日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of partiesCrushing Plant Design and Layout Considerations 911 CRUSHING PLANT DESIGN The number of crushing stages necessary to reduce ore to the proper size varies with the type of ore Hard ores like gold, iron, and molybdenum ores, may require as much as a tertiary crushing To design a good crushing plant one has to follow these three steps: 1 Crusher selection 2 Crusher layout and 3INTRODUCTION TO MINERAL PROCESSING FLOWSHEET DESIGN

How to design a crushing plant LinkedIn

2023年1月12日 Designing a crushing plant involves several key steps, including selecting the right equipment, determining the desired output, and identifying any environmental or regulatory constraints 1 The stone crusher plant consists of a crushing setup of excavators, feeders, primary and secondary crushers and screeners They all work together to crush stone as efficiently as possible Conveyors connect everything, moving the crushed material from one station to the next Stone crusher plant equipment is divided into two categories:Stone Crusher Plant Setup Machinery Partner2021年12月16日 Crushing Plants Spa Our engineers are experts in designing appropriate solutions to meet every customers need De longues années constamment orientées à la qualité et la fonctionnalité des produits ont Crushing Plants SpA

Influence of Natural Aggregate Crushing Process on Crushing

2021年7月27日 The design of a crushing plant by only relying on steadystate simulations will not generally provide the complete picture of the possible operating performance M Designing of the technological line in the SCADA system PROMOTIC In Proceedings of the 14th International Carpathian Control Conference, Rytro, Poland, 26–29 May 2013; pp 2023年2月7日 through crushing plant process reengineering to boost the quarry’s cash flow Pareto analysis of the product sales was carried out Designing a typical aggregate quarry involves multidisciplinary efforts to guarantee technical feasibility and commercial viability of the project, most importantly a commercial quarry whose primeAbdulraman SO and Olaleye B IJSER2021年3月18日 The main process of the CIP gold processing plant to extract gold from ore and convert it into pure metal can be divided into 6 steps: crushing, screening, grinding, classification, carbon slurry gold How Does A CIP Gold Processing Plant Work?

Physical Bauxite Processing: Crushing and Grinding of Bauxite

2022年1月23日 31 Introduction to Crushing and Grinding of Bauxite The most common initial process step to feed an alumina refinery with bauxite is the crushing or sizing of the raw bauxite material that is extracted from the mine The feed material is crushed or sized so that it is conveyable, as well as correctly dimensioned, for the next step in the process2016年7月12日 AllisChalmers Corp, over a century of crushing involve ment has led to an entirely new approach to crushing and screening plant design which relates to Bond's Third Theory of Comminution For those used to designing plants or selectingequipmentbased upon existing criteria, AllisChalmers' a proach will be easier to Scientific Methods to Design Crushing and Screening 2019年6月11日 The steps for designing the organic waste crusher involve determining a conceptual physical geometry, conducting mechanical design, and finally, developing a 3D working drawing Manufacturing and (PDF) 3D designing of an organic waste crusher

VWHPLQSHDWPLQLQJ IOPscience

2022年11月9日 In the crushing plant, a raw peat material is separated, mixed and crushed After crushing plant the separated peat material is transferred into the hopper of a mobile dewatering plant by belt conveyor After the material is conveyed to the stockpile These way semitrailers would not be fed near the excavator, so it could avoid sinking2016年4月23日 This paper involves the process of designing the crusher considering forces required for crushing and ergonomic factor that an operator needs The design of this machine is such that it would require optimum load to crush metals and will not strain the user or operator After the completion of design process, it isDESIGN OF MECHANICAL CRUSHING MACHINE IRJET2016年6月2日 The jaw opening is maintained at 1″ The crusher discharge, along with the grizzly undersize, is transported on a 14″ x 65′ conveyor with a slope of 4 3/8″ per foot at 150 feet per minute to the fine ore bin The conveyor is powered with a 2Hp, 1200rpm, fancooled, totally enclosed ball bearing motorMineral Processing Plant Design Construction Example

Sandvik FastPlant™ Crushing Screening Plant SRP

Simply choose the crushing and screening plant that matches your needs, order, install and start crushing There’s no need to spend hours designing or modifying your solution Backed by Sandvik 365 Sandvik 365 delivers value throughout the entire lifecycle of the plant, to keep your operation running productively and efficiently yearround 2016年2月10日 up This paper addresses the critical design parameters that will increase the crushing capacity of the plant to 35 tonnes per hour There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The paper analyses all of these steps Keywords Gold mining, crushing, Zimbabwe, jaw Design of a crushing system that improves the crushing 2012年10月15日 By L Winchip, engineering manager, and G Mangrich, regional sales manager, McLanahan Corp Several considerations need to be taken into account in designing an efficient crushing and screening Crushing and Screening AggNet

Baioni Crushing Plants – Crushing and Water

2 天之前 We are committed to designing the best plant solutions for crushing, recycling and wastewater treatment Baioni is a world partner in the development, design and production of machinery BAIONI 通过相关处理措施以最大限度地降低大豆压榨厂粉尘爆炸隐患,做到安全生产,保护员工和公司的财产。 The dusts in the soybean crushing plant are mainly organic dust, and the dusts are also divided into the soybean dust and containing hexane dust and the soybean meal dust The dust layer and the dust cloud 大豆压榨厂粉尘爆炸隐患及处理措施Hidden danger of dust 1 Considerations of stone crusher plant design The basic purpose of crushing ore is to achieve a certain particle size requirement for ore, raw materials or fuel In ore dressing, the purpose of crushing ore is: (1) supply the most reasonable ore feeding size for rod grinding, ball milling, or provide qualified grinding medium for autogenous Crushing Plant Design and Layout Considerations JXSC Mine

Enhanced Plant Design for Aggregate Processing AggNet

2012年10月15日 The intention of this article is to provide an overview of matters to be considered when designing a crushing and screening plant, starting with a blank sheet – when planning a plant upgrade or extension, preexisting factors may overrule the ability to incorporate some or all of these considerations It is not intended to recommend specific 2014年8月21日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of parties These can include the owner’s Setting up of crushing plant: design and layout considerations2015年10月15日 Steadystate modelling and simulation tools are widely used in designing of a new process for industrial coarse comminution circuit (crushing plant) (NapierMunn et al 1996;King 2001)(PDF) Crushing Plant Dynamics ResearchGate

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 Today, stationary, semimobile and m obile crushing plants with capacities ranging from 500 to more than 10,000 t/h are used prov ing for crushing and processing hard roc k, limestone, coal,2021年8月25日 This paper presents a method of integrating an experimental and datadriven approach for calibration and validation for crushing plant equipment and a process model Tuppurainen, D; Bearman, R Designing Comminution Circuits with a MultiObjective Evolutionary Algorithm In Proceedings of the 2005 IEEE Congress on Minerals Free FullText Applied Calibration and Validation