عنا

مرحبا هل يمكنني مساعدتك؟

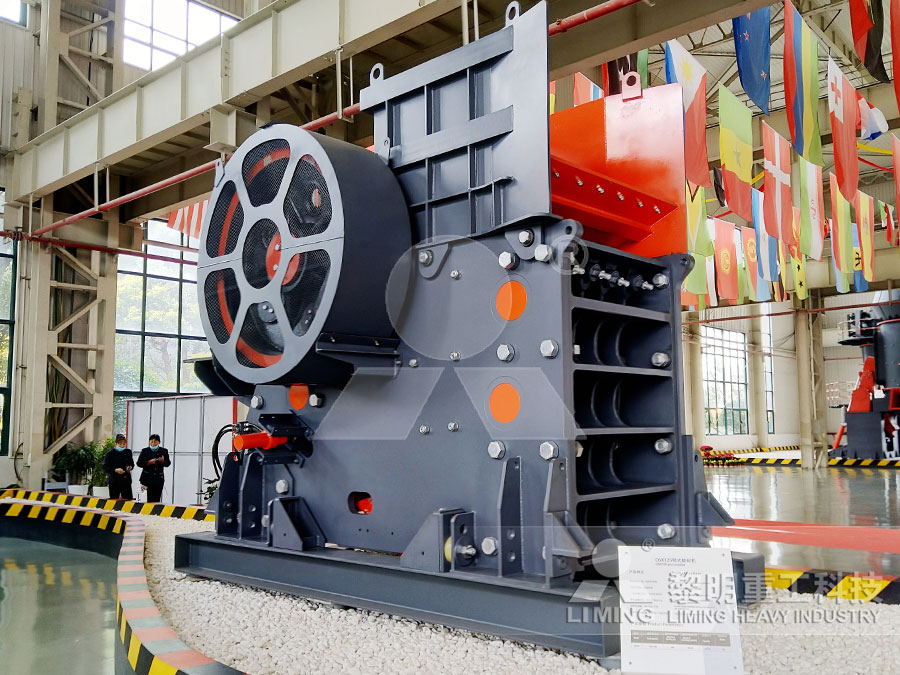

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Jaw Crushers In Malaysia Mining Operations

2022-02-10T01:02:27+00:00

jaw crushers in malaysia mining operationsmd GitLab

Open sidebar chengxinjia; ; RepositoryMinex MJC series of single toggle jaw crushers are mainly used for heavyduty continuous applications as primary crushers in aggregates production, mining operations and recycling applications This series includes Jaw Crusher – Minex SolutionsThere are three common crushers used at mining and processing plants, these designs are: Gyratory Crusher; Jaw Crusher; Cone Crusher; Crusher Types (jaw, cone, gyratory) Typically, the initial crushing stage is Jaw Crusher Explained saVRee

Malaysian Jaw Crusher Manufacturers Suppliers of Malaysian

Malaysian manufacturers and suppliers of jaw crusher from around the world Panjiva uses over 30 international data sources to help you find qualified vendors of Malaysian jaw 2013年3月17日 Jaw Crushers for gold mining and materials recycling Jaw Crushers are utilized for primary crushing of a multitude of materials in the actual mining, gold ore, iron jaw crusher in malaysia Mining Quarry PlantSupplying the quarry, mining, recycling and construction industries in Malaysia The Striker range of mobile cone crushers is a high performance, reliable machines suitable for use Crushers, Screens Conveyors in Malaysia Striker Built To

jaw crusher for mining LinkedIn

Published Jun 19, 2023 + Follow Jaw crushers are widely used in the mining industry as primary crushing equipment due to their ability to handle large feed sizes and process a Jaw Crushers S Mining Operations In Mexico Jaw Crushers S Mining Operations In Mexico FOB Reference Price: Get Latest Price 3 type of crusher for manganese ore mining Jaw Crusher In Malaysia Mining Operations MC Machinery2019年3月28日 Singletoggle jaw crushers; Doubletoggle jaw crushers; There are several other jaw crushers like bulldog jaw crushers and force feed jaw crushers But for reference, we’ll focus on the two most widely What Are Jaw Crushers and How Do They Work?

The 10 Best Crusher Manufacturers Brands in 2023

2023年6月25日 These include: See also The 10 Best Industrial Furnace Manufacturers Brands of 2023 Sandvik Manufacturing and Processing Solutions, the world’s leading manufacturer of metal cutting tools and tool systems, made of cemented carbide, diamond, cubic nitriding shed, special ceramics, and other hard materials2017年6月2日 Crushers Industrial crushers reduce large rocks, ore or waste materials to smaller sizes by impact or pressure to fracture or deform the material During the primary crushing operation, boulder size feeds How it Works: Crushers, Grinding Mills and 2017年6月30日 A review on the design and operations challenges of a single toggle jaw crusher is presented Strength and fracture toughness of the material to be crushed are intrinsic properties that determine (PDF) DESIGN AND OPERATIONS CHALLENGES OF

Gyratory Crusher (Gyratory Crushers Explained) saVRee

A primary crusher is designed to receive runonmine (ROM) rocks directly from the mines Gyratory crushers typically crush to reduce the size of aggregate to a maximum of about onetenth of its original size Gyratory crushers are always installed vertically orientated A gyratory crusher’s size is classified by:Jaw crushers are generally defined by their opening size For example, a 900x650 mm crusher refers to a crusher with an inlet measuring 900 mm by 650 mm The main parts and main technical parameters of a jaw crusher are presented below 1 Feed Chute Mining Eng Msc Necati Yıldız, Ore Dressing and Enrichment Book What Is A Jaw Crusher MEKAThe APC series stone cone crusher machine is usually to crush midhard and above midhard ores and rocks It is a popular stone crusher for sale Philippines in manufactured sand production, aggregates production, and mining operations The cone stone crusher sandmaking machine is used for secondary, tertiary crushing stagesStone Crusher Plant Philippines for Mining Hotsale 50

Jaw crusher EB

For example, the patented swing jaw and front wall design absorb load peaks during operations In our Pro series, we offer the following models (see more details below) Jaw Crusher EB 2015 Pro with a capacity range of 600 – 1,600 tph; Jaw Crusher EB 1612 Pro with a capacity range of 400 – 1,200 tph2018年2月4日 It offers both an ECO mode and an engine information page on its jaw crushers "ECO mode delivers an environmentally friendly aspect of better fuel efficiency, as well as higher throughput and lower noise levels When the crusher works at a lower power demand, the panel lowers the engine rpm from 1,900 to 1,750 for lower fuel Tracked Jaw Crushers: uses, benefits and how technology is 2020年3月19日 Best suited for secondary crushing applications, cone crushers are designed to crush presized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher Cone crushers can form finished products down to 12mm or less Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but Selecting the right crusher for your operations Quarry

Crushers All crusher types for your reduction needs

Crushers are machines used to reduce the size of rocks, stones and ore They are often utilized in aggregates production, construction material recycling and in mining operations offering covers different gyratory crushers, jaw crushers, cone crushers and impact crushers – optimized for any size reduction need2022年11月21日 Average throughput rate of singletoggle jaw crusher, standard version, tolerance ± 10% Doubletoggle jaw crushers Design Doubletoggle jaw crushers are equipped with a doubletoggle system, which is con trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately Industrial Solutions Jaw crushers ThyssenKrupp2023年1月5日 The jaw crusher works by using a moving jaw and a fixed jaw to crush and grind the rocks The material is fed into the jaw crusher by a vibrating feeder, and then it is crushed between the two jaws The jaw How Does a Jaw Crusher Work? Industrial

Jaw crusher price jaw crusher plant Jaw crusher machine mining

2023年9月12日 This makes jaw crushers ideal for reducing the size of raw materials in mining and construction applications 2 Mining Jaw Crusher: A Key Player In mining, jaw crushers are vital for several 2023年8月12日 A mining crusher is a machine used to reduce large rocks into smaller pieces Crushers are designed to handle a range of materials It is from ores to coal and various minerals used in the mining industry There are several types of crushers commonly used in mining operations: Jaw Crusher Gyratory CrusherMining Crushers AllMinings2019年12月10日 Operation of a dodge type jaw crusher In the Dodge type jaw crushers, the jaws are farther apart at the top than at the bottom, forming a tapered chute so that the material is crushed progressively smaller and smaller as it travels downward until it is small enough to escape from the bottom openingType of crushers and their difference JXSC Mining

Jaw Crusher SpringerLink

2023年6月21日 The moving jaw rotates around the eccentric axis as well as swings around the same center (Fig 2)By removing the moving jaw suspension shaft and the front toggle plate of simple pendulum jaw crusher, and suspending the moving jaw on eccentric shaft to combine the connecting rod and the moving jaw into whole, a compound pendulum jaw crushers (C200 series) are 1600 x 2514 mm with motors rated at 400 kW The largest particle that can enter the opening of the jaw crusher can be estimated by: Largest particle size= 09 x gape The largest particle to report to the jaw crusher is typically defined by the drilling pattern in the mine Typical Jaw Crusher CharacteristicsAMIT 135: Lesson 5 Crushing – Mining Mill Operator Training2022年11月21日 these machines Changing mining and processing techniques demand, besides new materials and design methods, continuous development of the products thyssenkrupp gyratory crushers represent today’s stateoftheart They are designed for high performance and, at the same time, costeffective operation, ie low servicing and Industrial Solutions Gyratory crushers ThyssenKrupp

Crushing Systems

2020年4月15日 crushers offer more flexibility in production to meet customer requirements Design Raptor cone crushers have been designed with input from plant operations and maintenance people around the globe This input has led to many designs and features that reduce maintenance time and increase productionHow Jaw Crushers Are Sized Jaw crushers are sized based upon the dimensions of the top feed inlet (gape) or the dimensions of the jaws For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top ie the opening), and each jaw will have a 54inch widthJaw Crusher Explained saVRee2019年6月28日 Introduction Crushers play an important role in the material handling process for underground mine operations The main purpose of a crusher is the size reduction of the feed This size reduction Crushers QueensMineDesignWiki

RIVLQJOH WRJJOHMDZ FUXVKHU

Singletoggle jaw crushers are used at the beginning of this process [7] and are among the main machines for crushing Jaw crushers are widely used in many different industries to crush brittle materials with various strength Usually, jaw crushers are put at the beginning of the technological lines of oredressing and sample cutting2023年10月24日 These suppliers contribute significantly to the mining industry by providing durable, highperformance jaw crushers that facilitate smooth and uninterrupted production processesLimestone Mining Jaw Crusher Supplier LinkedInCrushers Mining operations use crushers, commonly classified by the degree to which they fragment the starting material, with primary and secondary crushers handling coarse materials, and tertiary and quaternary crushers reducing ore particles to finer gradations Each crusher is designed to work with a certain maximum size of raw material, and often Crushers : VIRIDIS Engineering

Construction Working and Maintenance of Crushers for

2018年12月26日 2 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance Content Chapter Title Page No 1 Crushers for Bulk Materials 3 2 Gyratory Crushers 8 3 Jaw Crushers 12 4 Cone Crushers 20 5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 年8月20日 Crushers are used to break up large pieces of rock and bulk materials The size of the eventual pieces depends largely on the type of crusher unit used; some models are designed to merely break large stones into manageable segments, while others are engineered to reduce an entire workpiece to dust Crushers are widely used in mining, More About Crushers ThomasnetThe capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation The capacity is primarily a function of: 1 crusher design characteristics such as width and depth of the crushing chamber, 2 Jaw Crusher an overview ScienceDirect Topics

Mobile Crusher Plant in The Philippines Wheeled Or

Jaw mobile crushing plant is also known as a coarse crushing tire mobile crushing station Therefore, it is usually used for primary crushing equipmentThe small mobile jaw crusher plant adopts an integrated operation method, which eliminates the installation of complex site infrastructure and auxiliary facilities The overall structure of the mobile jaw crushing 2019年5月30日 Jaw crushers have a multitude of advantages, including: Ability to handle many different types of materials—from hard granite to reclaimed asphalt pavement (RAP) and more—without displaying as 5 Common Questions about Jaw Crushers Answered2023年2月22日 The most common types of rock crushers used in gold mining operations are jaw crushers, cone crushers, and impact crushers Jaw Crushers Jaw crushers are designed to crush the toughest materials through the use of a compressive force This makes them ideal for crushing hard, abrasive rocks and ores They are also easy to Gold Mining Rock Crushers and Crushing Plants: A Complete

Design of a crushing system that improves the crushing

2016年2月10日 ore can have a size of up to 400mm There are many types of crushers but the major ones are the jaw, gyratory and the cone crusher 241 Types of Crushers 2411 Jaw Crusher Jaw crushers operate by squeezing a rock particle placed between a fixed and a moving plate (jaw) Both plates could be flat or the fixed plate flat and the moving 2023年3月16日 Jaw crushers are commonly used in mining, construction, and recycling industries Impact crusher: This is a machine that uses highspeed impact forces to crush rocks or granite into smaller piecesWhat can I use to crush rocks or granite? LinkedIn2021年3月25日 These types of compression crushers are best suited for heavy mining, quarried materials, sand and gravel, and recycling applications They provide a reduction ratio of 3:1 to 6:1 Jaw Crushers feature a moving piece of steel (called the pitman) and a stationary piece of steel that form a Vshaped chamberMcLanahan What Type of Crusher Is Best for Primary Crushing?

Simplifying the crushing process Pit and Quarry

2019年5月10日 Typically, the minimum setting on most primary crushers is about 4 in to 6 in Jaw, gyratory and impact crushers are most often appropriate as primary crushers, although there can be overlap between primary and secondary machines 2 Secondary crushing Reduction ratios become an important consideration in secondary crushingThe Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a doubletoggle Jaw Crusher Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavyduty double McLanahan Jaw CrushersMechanical Crushing and Grinding Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Crushers Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer Crusher an overview ScienceDirect Topics

Mobile crushers

Mobile crushers are trackmounted rock crushing machines that are easily movable on and between production sites They are widely used in aggregates production, recycling applications, and in mining operations Mobile crushers can replace stationary crushing systems, which reduces the need for hauling and thus cuts operational costs2022年12月24日 Jaw crushers are utilized extensively in the industries of mining, metallurgy, building materials, ceramics, and engineering of massive minerals with small and medium particle size crushing [1,2,3]There are now more demands on crushers in terms of efficiency, energy use, and cost due to new issues including the rise in lowquality ore, Dynamics Analysis and Chaos Identification of Compound Pendulum Jaw 2023年10月25日 Jaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won’t have to be blasted down to a fine size jaws are designed to be significantly more reliable and have lower wear rates, maximizing production and minimizing wear parts Jaw Crushers

The 10 Best Crusher Manufacturers Brands in 2023

2023年6月25日 These include: See also The 10 Best Industrial Furnace Manufacturers Brands of 2023 Sandvik Manufacturing and Processing Solutions, the world’s leading manufacturer of metal cutting tools and tool systems, made of cemented carbide, diamond, cubic nitriding shed, special ceramics, and other hard materials2017年6月2日 Crushers Industrial crushers reduce large rocks, ore or waste materials to smaller sizes by impact or pressure to fracture or deform the material During the primary crushing operation, boulder size feeds How it Works: Crushers, Grinding Mills and 2017年6月30日 A review on the design and operations challenges of a single toggle jaw crusher is presented Strength and fracture toughness of the material to be crushed are intrinsic properties that determine (PDF) DESIGN AND OPERATIONS CHALLENGES OF

Gyratory Crusher (Gyratory Crushers Explained) saVRee

A primary crusher is designed to receive runonmine (ROM) rocks directly from the mines Gyratory crushers typically crush to reduce the size of aggregate to a maximum of about onetenth of its original size Gyratory crushers are always installed vertically orientated A gyratory crusher’s size is classified by:Jaw crushers are generally defined by their opening size For example, a 900x650 mm crusher refers to a crusher with an inlet measuring 900 mm by 650 mm The main parts and main technical parameters of a jaw crusher are presented below 1 Feed Chute Mining Eng Msc Necati Yıldız, Ore Dressing and Enrichment Book What Is A Jaw Crusher MEKAThe APC series stone cone crusher machine is usually to crush midhard and above midhard ores and rocks It is a popular stone crusher for sale Philippines in manufactured sand production, aggregates production, and mining operations The cone stone crusher sandmaking machine is used for secondary, tertiary crushing stagesStone Crusher Plant Philippines for Mining Hotsale 50

Jaw crusher EB

For example, the patented swing jaw and front wall design absorb load peaks during operations In our Pro series, we offer the following models (see more details below) Jaw Crusher EB 2015 Pro with a capacity range of 600 – 1,600 tph; Jaw Crusher EB 1612 Pro with a capacity range of 400 – 1,200 tph2018年2月4日 It offers both an ECO mode and an engine information page on its jaw crushers "ECO mode delivers an environmentally friendly aspect of better fuel efficiency, as well as higher throughput and lower noise levels When the crusher works at a lower power demand, the panel lowers the engine rpm from 1,900 to 1,750 for lower fuel Tracked Jaw Crushers: uses, benefits and how technology is 2020年3月19日 Best suited for secondary crushing applications, cone crushers are designed to crush presized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher Cone crushers can form finished products down to 12mm or less Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but Selecting the right crusher for your operations Quarry

Crushers All crusher types for your reduction needs

Crushers are machines used to reduce the size of rocks, stones and ore They are often utilized in aggregates production, construction material recycling and in mining operations offering covers different gyratory crushers, jaw crushers, cone crushers and impact crushers – optimized for any size reduction need