عنا

مرحبا هل يمكنني مساعدتك؟

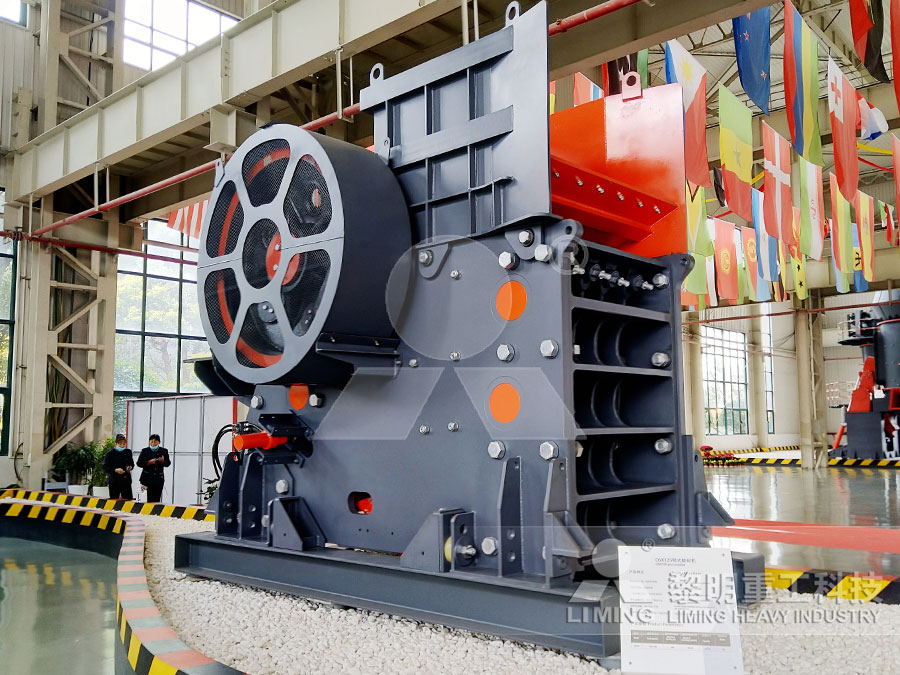

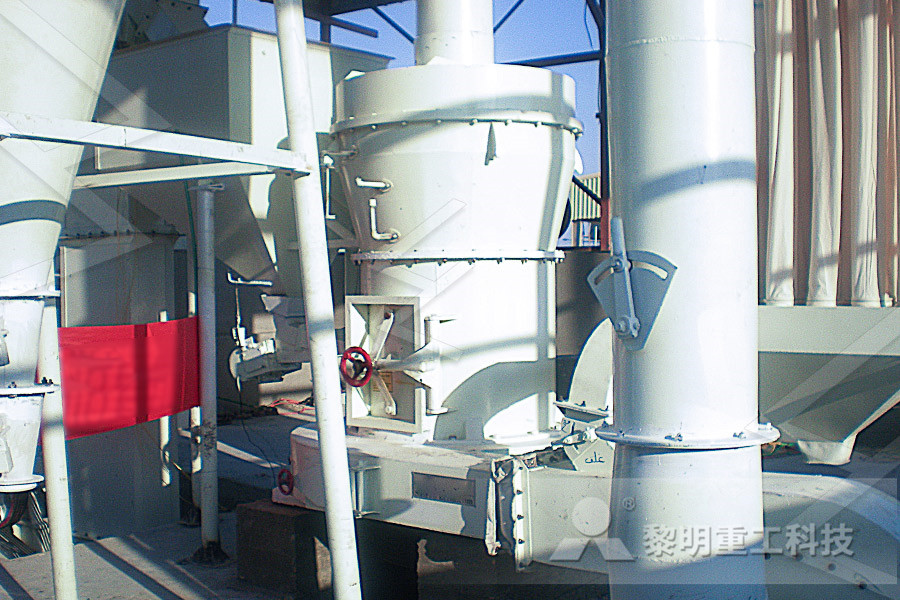

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

furnace induction furnace and ball mill manufacturer

2022-08-21T10:08:07+00:00

Leading Induction Furnace Manufacturer HighQuality and Reliable Furnaces

An induction furnace manufacturer specializes in designing and producing highquality induction furnaces These furnaces are used for various applications, including melting, Induction Furnace And Ball Mill Manufacturer induction furnace and ball mill manufacturer ball mill for induction furnace slag YouTube Sep 9, 2013 is an internationally renowned Induction Furnace And Ball Mill ManufacturerInduction Furnace Induction Heating Furnace is mainly used for heating the metal materials before shear it in forging, extruding, rolling field, and also for metal heat treatment process such as adjusting the quantity, quenching, Induction Furnace Supplier Melting Furnace

Grinding Ball induction heating furnace Forever Manufacturer

Forever Furnace can manufacture mining grinding ball production line,forging grinding ball production line and grinding ball production line for cement millMore details,please refer Our steel ball making machine is divided into two types: Steel ball hot rolling machine and steel ball forging machine Using round bars to make steel balls directly Phone: +86 Steel Ball Making heating furnace manufacturer supplierHeating way: Induction furnace Basic components:Induction furnace+skew rolling mill+roller quenching system+PLC console Typical Application: Hot rolled grinding media is a latest Grinding media hot rolling mill manufacturer supplier

induction furnace and ball mill manufacturer

European Impact Crusher SemiAutomatization, Standardization Combining outstanding manufacturing More HJ Jaw CrusherAluminium Gas Hydraulic Tilting Aluminum Melting Furnace, Material Loading Capacity (T): 5 ₹ 19,25,000 Get Latest Price Melting Material: Aluminium Material Loading Capacity (T): 5 Power Source: Gas Type Industrial Furnaces Foundry Furnaces Latest Find High Quality Induction Furnace And Rolling Mill Manufacturer Induction Furnace And Rolling Mill Suppliers and Induction Furnace And Rolling Mill Products at the Best Price induction furnace and rolling mill, induction furnace and rolling mill

Induction Furnace A Review ResearchGate

2023年10月13日 Induction furnace manufacturers saw the potential and started manufacturing bigger size/capacity furnaces By 198889 period 3 tonne per charge adding mill scale, if opening carbon of bath was 2023年10月30日 Induction Furnace product price in India ranges from 220 to 55,00,000 INR and minimum order requirements from 1 to 10 Whether you're looking for Induction Furnace, Induction Furnace Assembly Parts, 3 Ton Furnace with 1 Year Warranty etc, you can explore and find the best products from TradeindiaInduction Furnace Electric Induction Furnace Prices, Manufacturers 2022年11月4日 Furnace Operator Salary Outlook Furnace operators’ salaries vary depending on their level of experience, the company size and geographic location They may also earn additional compensation in the form of overtime Median Annual Salary: $41,500 ($1995/hour) Top 10% Annual Salary: $95,000 ($4567/hour)Furnace Operator Job Description: Salary, Duties, More

Induction furnaces for hot rolling mills Selit srl

At the beginning of the 2000s, SELIT collaborated with ARVEDI steel mills in the development of continuous casting technology in flat laminates, called ARVEDI ESP, establishing itself as the first world manufacturer to have created a 36000kW – 10 kHz induction temperature recovery system able to raise and equalize the temperature of 2015年9月10日 Ball, rod, or hammer mills can be used to reduce oxides and nonmetallic particles to fine powders for ease of removal during screening increased strength and hardness by blending aluminum and hardening agents in an electric induction furnace The process steps include charging scrap, melting, adding and blending the hardening agent,AP42, CH 128: Secondary Aluminum Operations US EPAWe will reply you in 24 hours We provide Electric arc furnace designing, manufacturing, installation, and commission of the equipment with "turnkey" service ELectric arc furnace is using electricity as the fuel source, and utilizes the arc high temperature produced by electrode and furnace charge to heat and melts the furnace chargeElectric Arc Furnace Design, Manufacture, Install "Turnkey"

Grinding media hot rolling mill manufacturer supplier

Heating way: Induction furnace Basic components:Induction furnace+skew rolling mill+roller quenching system+PLC console Typical Application: Hot rolled grinding media is a latest grinding media rolling technology, it is the technical breakthrough of grinding media milling manufacturing process, and it is replacement of casting steel ball 2011年8月1日 Abstract and Figures A new generation of industrial induction melting furnaces has been developed during the last 25 years Present practices followed in Induction Furnaces are discussed in this (PDF) Induction Furnace A Review ResearchGateInductotherm Group Australia along with many local agents provide an extensive network of induction sales and service engineers for the areas of South East Asia, Australia and New Zealand The Inductotherm Group design and manufacture the most advanced induction melting furnaces for melting, holding and pouring for virtually all metal and Inductotherm Group Australia Induction Specialists

Desktop High Speed Vibrating Ball MillThe best lab furnace

2013年7月17日 Desktop High Speed Vibrating Ball Mill with 50mL Alumina Jar , 2 Years Warranty Model: MSKSFM3 Description: MSKSFM3 (Updated since 7/17/13) is a compact high speed vibrating ball mill for making small quantity of powder samples at easy and fast with improved vibration design It has higher impact energy created by three 2017年11月22日 Mill along with already operational Induction Furnaces P a g e 7 Nandan Steels and Power Limited VillageSondra, Siltara Industrial Growth Centre, Raipur (CG) Existing Facilities and Capacity Product Facility Capacity (in TPA) Remark [A] MS Billets Induction Furnaces 7000000 NoteAt present the billets are being cooled, in futurePre Feasibility ReportElectrotherm ET provides induction furnace for ferrous metals (iron steel) that gives you superior performance minimizes the heat loss during the process We are an ISO 9001:2015 certified public limited company Induction Melting Furnace Electrotherm ET

Steelmaking in Induction Furnace – IspatGuru

2018年5月24日 Induction furnace is a type of electric melting furnace which uses electric current to melt metal The principle of induction melting is that a high voltage electrical source from a primary coil induces a low 2023年11月2日 A furnace crucible is used for melting and casting of metals and certain alloys This is the part of the induction furnace that holds molten metal during melting processes The furnace crucible is made up of graphite which makes it a high quality induction furnace graphite crucible The furnace crucible is best applicable to the Furnace Crucibles, Induction Furnace Graphite Crucible Manufacturer2021年5月19日 The electric Induction furnace is a power supply device that converts 50HZ AC power into an intermediate frequency (above 300HZ to 1000HZ) It converts threephase AC power after rectification into DC, and then converts the DC into an adjustable intermediate frequency current, which is supplied by a capacitor with the intermediate Rolling Mill Production Line: How Does An Electric Induction Furnace Work?

Industrial Furnaces and Furnace Coils Metal Melting Furnace

Ball Mill Furnace are smaller than common ball mills and mainly used in laboratories for grinding sample material down to very small sizesA planetary ball mill consists of at least one grinding jar which is arranged eccentrically on a socalled sun wheel The direction of movement of the sun wheel is opposite to that of the grinding jars (ratio: 1:2 or 1:1 or else)Find the best Induction Melting Furnaces in Ludhiana, offering 99 options at the latest price Discover a wide range of induction melting furnaces from top manufacturers, dealers, and distributors across Ludhiana Explore available options in nearby cities like Yamunanagar, Mandi Gobindgarh, Patiala, and moreInduction Melting Furnaces In Ludhiana Prices, Manufacturers Induction Heating for the Steel Industry Induction technologies offer a cleaner solution to your heating needs when compared to alternate heating methods – like combustion furnaces which many rolling mills use todayAdditionally, induction systems offer a better return on your investment, lower operating costs, higher quality end products and reduced metal Induction Heating for the Steel Industry Inductotherm Corp

Rolling Mill Production Line: Presentation on Electric Arc Furnace

2021年4月2日 The electric arc furnace is an electric furnace that uses high temperature produced by electrode arc to smelt ore and metal When the arc is formed by gas discharge, the energy is concentrated and the temperature of the arc zone is above 3000 ℃ For smelting metals, EAF is more flexible than other steelmaking furnaces, which can Chinese Aluminum Melting Furnace Total 773 manufacturers suppliers found with 2,319 productsChinese aluminum melting furnace Manufacturers2020年8月5日 Author : hani Time : 2020/08/05 Ladle refining furnace is important metallurgical equipment for refining molten steel from primary refining furnace (electric arc furnace, openhearth furnace, and What Is the Ladle Refining Furnace? Hani Tech

Lab Equipment Manufacturer Supplier Across

Ball Mills High Energy Ball Mill ; Planetary Ball Mills ; Jars and Parts ; Distillation Short Path Distillation 2L ; 5L ; Vacuum Furnace Induction Melting 2000°C 13 Kgs Capacity Jacketed Stainless Steel Vacuum Inductotherm offers induction silicon melting to reduce the cost of solargrade silicon Induction induction furnaces can significantly increase the volume of production The earlier generation of furnaces and silicon processing techniques, designed for small volume semiconductor devices, cannot satisfy the growing demand Induction furnaces Induction Silicon Melting Inductotherm Group Australia2020年6月18日 Among electric arc furnace and induction furnace routes, the induction furnace is preferred because of its high yield (9596% for IF and 9293% for EAF), better electrical efficiency, and low Energy Balance in Induction Furnace and Arc Furnace Steelmaking

Frequently Asked Questions About the Electric Induction Furnace

2021年5月25日 The burning rate of alloy elements in an electric induction furnace is lower than that in electric arc furnaces, especially in charging and returning materials 5 Carbon Increase Electric induction furnace is based on the principle of induction heating to melt metal charge without carbon enrichment in molten steel2020年3月3日 Other heat losses from the furnace = @ 4% of total heat input (average) It is found by calculation (Example 167) for EAF of capacity 180 t and 76 m diameter, the radiation loss per tonne of liquid steel is 67 kWh Other heat losses from the furnace = 004 × 825 = 33 kWh (If total heat input for EAF is 825 kWh/t)Electric Furnace Processes SpringerLinkHSN Code HSN Description Industrial or laboratory furnaces and ovens, including incinerators, nonelectric parts Converters, ladles, ingot moulds and casting machines, of a kind used in metallurgy or in metal foundries ingot moulds and ladles : ladles Industrial or laboratory electric furnaces and ovens (including Precision Engineered Ladle and Industrial Furnace Manufacturer

Principle of Induction Furnace: Shapet Induction Company

The first Induction Furnace for melting metals was patented by Edward Allen Colby around 1900 The first practical usage Induction Furnace of was by Kjellin in Gysinnge, Sweden in 1900 The first steel was made in an Induction Furnace in the United States in 1907 in a Colby furnace near Philadelphia The first Induction Furnace for 3phase Inductotherm is the principal supplier of induction furnaces and power supplies to the world’s leading vacuum system manufacturers and precision investment casters, alloy manufacturers and anyone needing the highest quality molten metal Inductotherm Vacuum Furnaces are designed specifically for operation in high vacuum environments and FAQs: Induction Furnaces Inductotherm Corp2015年1月8日 Induction furnace manufacturers saw the potential and started manufacturing bigger size/capacity furnaces By 198889 period 3 tonne per charge induction furnaces were installed (became standard) all over India The chemistry of melt was adjusted by adding mill scale, if opening carbon of bath was more Good quality of Induction Furnace A Review Engg Journals

Portable Smelter for Sale, Electric Induction

2023年11月2日 The total melting time for each batch of metal is 2 minutes The portable melting kit by Superbmelt is equipped with the latest IGBT induction heating saves about 15 to 30% of energy use The maximum ABP’s IFM furnace system is a high performance induction melting furnace designed for the most demanding foundries of the world IFM furnaces are renowned for fast melting times, high reliability, safety and ease of Melting ABP InductionThis site offers visitors steel industry news from around the globe; steel pricing data (including raw material prices); steelmaking plant and equipment capex costs; and steel market knowledge (supply and steel industry news costs prices mci consultants

125 Iron And Steel Production US EPA

2015年9月10日 12516 Steelmaking Process — Open Hearth Furnaces The open hearth furnace (OHF) is a shallow, refractorylined basin in which scrap and molten iron are melted and refined into steel Scrap is charged to the furnace through doors in the furnace front Hot metal from the blast furnace is added by pouring from a ladle through a trough positioned2 天之前 The hydraulic jewelry melting furnace is used for large industrial melting applications because it is capable of melting up to 50 kg to 250kg of ferrous and nonferrous metals The maximum power required for melting is between 15kw to 160kw The induction heating technology helps to save up to 15 % to 30% of energyJewelry Melting Furnace, Electric Induction Melting HSN Code HSN Description 73 Articles of iron or steel 8416 Furnace burners for liquid fuel, for pulverised solid fuel or for gas; mechanical stokers, including their mechanical grates, mechanical ash dischargers and similar appliances Industrial or laboratory furnaces and ovens, including incinerators, nonelectric furnaces and ovens for the Wholesaler of Industrial Furnaces Ball Mill Machine by

Rolling Mill Production Line: Heating Furnace What You Need

2021年3月10日 The heating furnace pressure should be set at 0 ~ 30Pa higher than atmospheric pressure If the furnace pressure is too high, the charging port, discharging port, observation hole and other opening parts will be exposed to fire The results are as follows: (1) the furnace gas loss increases, which increases the heat loss; (2) SO 2 and other Induction Smelting Furnace Total 281 manufacturers suppliers found with 843 productsInduction smelting furnace Manufacturers Suppliers, China induction 2021年1月20日 the induction furnace but also reduce the effective diameter of the furnace making charging a much difficult operation This also brings about an increase in the amount of slag with about 10 kWh energy loss per 1% slag that is f[18] ormed [19] To accurately determine the melting time of an induction furnace campaign,Melting Time Prediction Model for Induction Furnace

Induction Furnace A Review ResearchGate

2023年10月13日 Induction furnace manufacturers saw the potential and started manufacturing bigger size/capacity furnaces By 198889 period 3 tonne per charge adding mill scale, if opening carbon of bath was 2023年10月30日 Discover 442 products from Induction Furnace manufacturers, suppliers, distributors, and dealers across India Induction Furnace product price in India ranges from 220 to 55,00,000 INR and minimum order requirements from 1 to 10Induction Furnace Electric Induction Furnace Prices, Manufacturers 2022年11月4日 Furnace Operator Salary Outlook Furnace operators’ salaries vary depending on their level of experience, the company size and geographic location They may also earn additional compensation in the form of overtime Median Annual Salary: $41,500 ($1995/hour) Top 10% Annual Salary: $95,000 ($4567/hour)Furnace Operator Job Description: Salary, Duties, More

Induction furnaces for hot rolling mills Selit srl

At the beginning of the 2000s, SELIT collaborated with ARVEDI steel mills in the development of continuous casting technology in flat laminates, called ARVEDI ESP, establishing itself as the first world manufacturer to have created a 36000kW – 10 kHz induction temperature recovery system able to raise and equalize the temperature of 2015年9月10日 Ball, rod, or hammer mills can be used to reduce oxides and nonmetallic particles to fine powders for ease of removal during screening increased strength and hardness by blending aluminum and hardening agents in an electric induction furnace The process steps include charging scrap, melting, adding and blending the hardening agent,AP42, CH 128: Secondary Aluminum Operations US EPAWe will reply you in 24 hours We provide Electric arc furnace designing, manufacturing, installation, and commission of the equipment with "turnkey" service ELectric arc furnace is using electricity as the fuel source, and utilizes the arc high temperature produced by electrode and furnace charge to heat and melts the furnace chargeElectric Arc Furnace Design, Manufacture, Install "Turnkey"

Grinding media hot rolling mill manufacturer supplier

Heating way: Induction furnace Basic components:Induction furnace+skew rolling mill+roller quenching system+PLC console Typical Application: Hot rolled grinding media is a latest grinding media rolling technology, it is the technical breakthrough of grinding media milling manufacturing process, and it is replacement of casting steel ball 2011年8月1日 Abstract and Figures A new generation of industrial induction melting furnaces has been developed during the last 25 years Present practices followed in Induction Furnaces are discussed in this (PDF) Induction Furnace A Review ResearchGateInductotherm Group Australia along with many local agents provide an extensive network of induction sales and service engineers for the areas of South East Asia, Australia and New Zealand The Inductotherm Group design and manufacture the most advanced induction melting furnaces for melting, holding and pouring for virtually all metal and Inductotherm Group Australia Induction Specialists

Desktop High Speed Vibrating Ball MillThe best lab furnace

2013年7月17日 Desktop High Speed Vibrating Ball Mill with 50mL Alumina Jar , 2 Years Warranty Model: MSKSFM3 Description: MSKSFM3 (Updated since 7/17/13) is a compact high speed vibrating ball mill for making small quantity of powder samples at easy and fast with improved vibration design It has higher impact energy created by three