عنا

مرحبا هل يمكنني مساعدتك؟

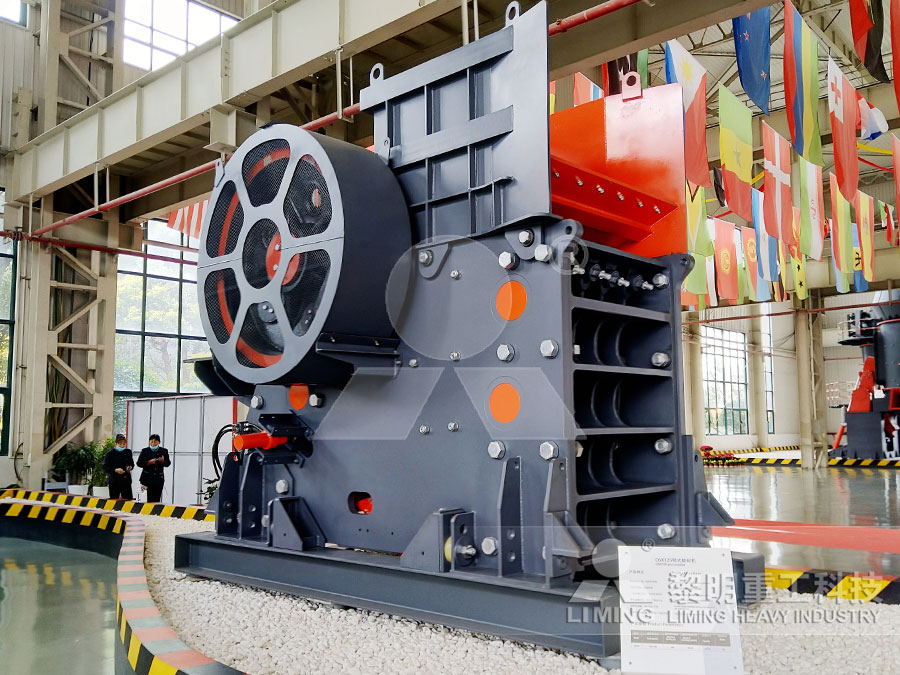

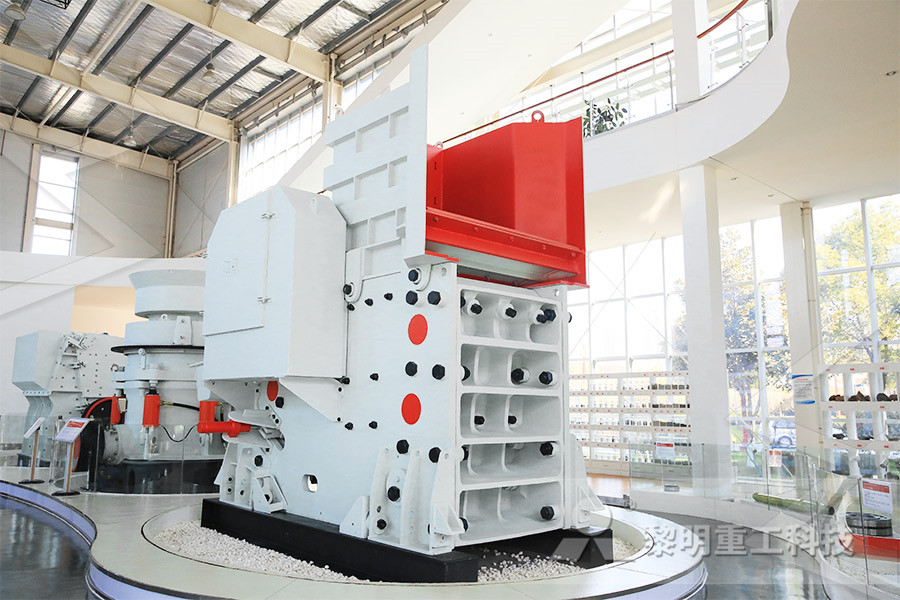

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

jaw crusher and analysis

2023-01-01T15:01:02+00:00

Jaw Crusher ScienceDirect

2016年1月1日 Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kW Crushers of this size are manufactured by Locomo, () and others The crusher is the C 200 2022年12月24日 A dynamic model of the working mechanism of a compound pendulum jaw crusher with clearance is established by the Lagrange multiplier method (LMD) based on the LN contact force model Dynamics Analysis and Chaos Identification of The main fields of application for a jaw crusher include building materials, mineralogy and metallurgy, ceramics and glass, materials science and environmental analysis They Retsch : 产品 : 粉碎设备 : 颚式粉碎仪

Jaw Crusher an overview ScienceDirect Topics

Jaw crusher: The material is crushed between a fixed jaw and a mobile jaw The feed is subjected to repeated pressure as it passes downwards and is progressively reduced in 2019年12月11日 The analysis and evaluation involved data collection from existing quarries The results show that an external diameter/offset ratio within the average of Performance optimization of jawtype rock crushing 2022年9月20日 Jaw crusher Optimisation This study reports on the design optimisation of the swinging jaw crusher plate Jaw crusher machines are used in the mining and Optimisation of the swinging jaw design for a single toggle jaw crusher

(PDF) Failure rate analysis of Jaw Crusher: a case

2019年1月2日 Failure rate analysis of Jaw Crusher: a case study Authors: Ravi Sinha Indian Institute of Technology (ISM) Dhanbad A K Mukhopadhyay Abstract Failure of crusher components has considerable2015年7月21日 This paper considers the methods for analysing failures of jaw crusher and its critical components in a mineral processing plant using statistical tools namely life Failure analysis of jaw crusher and its components using 2021年7月20日 The objective of this project is to make a 3D model of the swing jaw plates of jaw crusher and study the static and modal analysis behavior of the swing jaw plates Design and Analysis of Swing Jaw Plates of Jaw Crusher

Failure rate analysis of Jaw Crusher: a case study

2019年1月2日 Failure rate analysis of Jaw Crusher: a case study R S Sinha A K Mukhopadhyay Sādhanā 44, Article number: 17 ( 2019 ) Cite this article 374 Accesses 3 Citations Metrics Abstract Failure of crusher 2023年10月25日 Abstract: A dynamic model of the working mechanism of a compound pendulum jaw crusher with clearance is established by the Lagrange multiplier method (LMD) based on the LN contact force model and Dynamics Analysis and Chaos Identification of 2022年1月30日 In jaw crusher, another important analysis is breakage of the particle In particle breakage model, two types of approach are used widely which are Abt10 and Tavares model In this work, Abt10 model is used Abt10 model is developed by the Julius Kruttschnitt Mineral Research Centre (JKMRC) [9] The Abt10 particle breakage Improvement of Jaw Crusher Design by DEM FEA

Open Access proceedings Journal of Physics: Conference

2021年12月4日 Analysis for Cavity Shape of Single Toggle Jaw Crusher Xiaoqin Zhong, Xiaojian Niu, Qiqiang Ji et alInfluence of technological load on the stability of synchronous antiphase motion of the jaws of a vibratory crusher G Altshul, A Gouskov and G PanovkoThe Influence of the Structure of Double Toothed Roller Crusher on the Crushing Effect 2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling A laboratory analysis was also conducted using Xray Fluorescence (XRF (PDF) SIZE REDUCTION BY CRUSHING METHODS2019年1月2日 The present paper deals with failure analysis of rock crusher and its critical components using total time on test (TTT)plot and other statistical tools TTTplot has proven to be a useful tool (PDF) Failure rate analysis of Jaw Crusher: a case study

Energy consumption of a laboratory jaw crusher during

This paper presents the measurement and analysis of energy consumption of a laboratory jaw crusher during concrete recycling A method was developed to estimate the power requirements of a labscale jaw crusher Jaw crusher operates by compressing the feed material between a fixed and a moving jaw back and forth in an eccentric cyclic 2017年5月1日 Abstract In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher Previously, jaw crushers were modelled in regard to certain aspects, for example, energy consumption (Legendre and Zevenhoven, 2014) or kinematics (Oduori et al, 2015) Approaches to date have been mainly property specificA fundamental model of an industrialscale jaw crusherAccording to Chinese jaw crusher manufacturer’s data [ 21 ], the PE 400 by 600 single toggle jaw crusher has 30 kW motor power and an input eccentric shaft speed of 275 rpm or 287979 radians per second Assuming that the input speed is constant, the input torque is found to be 10417 kNmAnalysis of the Single Toggle Jaw Crusher Force

Small Scale Mechanized Stone Crusher, Mechanical Design

2021年7月26日 The purpose of this project is to evaluate the kinematic and static force analysis of a single toggle jaw crusher that employs the simple technology of a four bar mechanism, and design a small scale mechanized jaw crusher for crushing the stones into aggregates This mechanism will help 23 JAW CRUSHER COMPONENTS 2022年7月13日 Different Types of Jaw Crusher: Jaw crusher can be divided into two according to the amplitude of motion of the moving face The different types of Jaw Crushers are Blake Type Jaw Crusher and Dodge Type Jaw Crusher II LITERATURE REVIEW Shyam SundarV has published a paper on "OPTIMUM DESIGN AND ANALYSIS OF February 2018, Volume 5, Issue 2 JETIR (ISSN 2349 5162) 2022年3月22日 After analysis and comparison, the jaw plate with three additional teeth may produce less dust in practical application The crushing efficiency is increased by about 10%, and the amount of dust generated is significantly reduced Fastening the jaw plate The jaw crusher generates frequent impact loads during the operationAnalysis of Dust Generation and Removal Methods in Jaw Crusher

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 Patel KS, Qureshi U (2016) Design and finite element analysis of swing jaw plate of jaw crusher with stiffener Int J Adv Eng Res Developm 3(9):53–59 Google Scholar Korman T, Bedekovic G, Kujundzic T, Kuhinek D (2015) Impact of physical and mechanical properties of rocks on energy consumption of jaw crusher1) Obtaining the size or surface area required for the use of the ore or material 2) Allowing ease of transportation and storage 3) Separating the different minerals contained within the ore and to release them from one What Is A Jaw Crusher MEKA2019年1月2日 12 The jaw crusher Crushing is the first stage of size reduction of mined rocks Primary crushers are heavyduty machines, used to reduce the runofmine (ROM) ore down to a size suitable for easy handling A line diagram of a double toggle jaw crusher and its main components is shown in figure 2 The jaws are set at an angle to each otherFailure rate analysis of Jaw Crusher: a case study Sādhanā

Impact of physical and mechanical properties of rocks on

2015年1月1日 This paper presents the measurement and analysis of energy consumption of a laboratory jaw crusher during concrete recycling A method was developed to estimate the power requirements of a lab 2021年3月10日 Abstract In this article, a model of the interaction between the jaw of a vibratory jaw crusher with the rock under processing in the form of a lump material is considered To describe the motion of the rock and its sequential fracture into finer fragments, the crushing chamber is divided into zones of equal height In each current Modeling of the Interaction between a Rock Being Processed 2019年1月25日 12 The jaw crusher Crushing is the first stage of size reduction of mined rocks Primary crushers are heavyduty machines, used to reduce the runofmine (ROM) ore down to a size suitable for easy handling A line diagram of a double toggle jaw crusher and its main components is shown in figure 2 The jaws are set at an angle to each otherFailure rate analysis of Jaw Crusher: a case study Springer

Performance Parameters of Jaw Crushers Download Table

In this study, the effects of three different choke feed level (1/1, 1/2, and 1/4) and four different effective reduction ratios (25, 5, 10, and 20) depend on the capacity of the crusher of the 2019年12月11日 The analysis and evaluation involved data collection from existing quarries The results show that an external diameter/offset ratio within the average of 10:1 can be considered for the offset calculation of a jawtype crusher shaftPerformance optimization of jawtype rock crushing 2016年6月1日 More, “A Design Analysis of Swing Jaw Plates of Jaw Crusher”, nternational Journal of Enhanced Research in Science Technology Engineering, ISSN: 2319 7463 Vol 3 Issue 4, April2014, pp (PDF) Optimization of Effect of Without Stiffener on Swing Jaw Crusher

Cause Analysis and Problems Solving of Jaw Crusher

2022年3月22日 Cause analysis: 1 The casting has serious defects such as dense pores 2 Unqualified brackets and bracket pads are used When the crusher is in strong impact, the brackets are not selfbreaking 3 The movable jaw is displaced in the frame, and the bottom end hits the side guard plate2015年7月21日 Factorial design is used to determine failure rates using shape parameter, scale parameter and time failed data Failure rates of jaw crusher and its components are examined by 2 3 full factorial designs with two levels (high level and low level) and three variables High level is indicated as +1 and low level as −1Failure analysis of jaw crusher and its components using 2022年12月24日 characteristics of the PE250 × 400 compound pendulum jaw crusher in terms of jaw speed, acceleration and vibration force at a drivin g speed of 30 rad/s and a clearance size of 006 mm(PDF) Dynamics Analysis and Chaos Identification

(PDF) Automation experimental studies of grinding process in jaw

2018年12月1日 The grinding process in the jaw crusher was chosen as the process for the study Conducting experimental studies of crushing processes is a timeconsuming process that takes considerable time2015年4月1日 The equations obtained in this paper should be useful in further studies on the mechanics and design of the single toggle jaw crusher The Locus of Point P1 for One Complete Cycle of Motion (PDF) Analysis of the Single Toggle Jaw Crusher Kinematics2021年5月1日 Legendre D Numerical and experimental optimization analysis of a jaw crusher and a bubble column reactor, Dissertation, Åbo Akademi University, Turku, (2019) Google Scholar [32] Itaävuo P, Vilkko M and Jaatinen A Indirect particle size distribution control in cone crushers In 16th IFAC Symposium on automation in mining, mineral and Investigating the effects of feeding properties on rock breakage by jaw

RIVLQJOH WRJJOHMDZ FUXVKHU

2 Factors affecting jaw crusher capacity The mathematical model of the working process of the crusher should take into account many factors Operating experience and investigations have shown that the performance of jaw crushers significantly depends on their design and the motion law of its function element – the moving jaw [5], [6]2019年1月1日 Particle size distribution curves of recycled aggregates from building demolition concrete crushed by jaw and impact crushers The jaw crusher produced 60% of coarse aggregates in weight, whereas the impact crusher produced 49% coarse aggregates The proportion of particles finer than 015 mm is around 7–8% weight for both crushing Concrete aggregates properties crushed by jaw and2020年3月19日 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the quality of the (PDF) Influence of jaw crusher parameters on the quality of

Process flow sheet for the crushing tests, including sampling

The jaw crusher angle and rotating mass type are considered to study all particle sizes and reduction ratios obtained for three different motor operation speeds: 1500, 2000, and 2500 rpmInternational Journal of Energy Engineering 2016, 6(1A): 2331 DOI: 105923/sijee04 Theoretical Analysis of Swing Jaw Plates used inTheoretical Analysis of Swing Jaw Plates used in Heat 2019年8月24日 functioning Jaw crusher Most of these components are discussed below Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusher It forms the moving side of the jaw, while the stationary or fixed jaw forms the other It achieves its movement through the eccentric movement of the crusher main shaft It is Design and Construction of Rock Crushing Machine from

Jaw crusher kinematics simulation and analysis IJRES

2015年3月31日 jaw crusher Design study of the current status of the development of the jaw crusher and the future trend of development, and the design parameters of the detailed calculations And the most important is the use of ADAMS software crusher kinematics simulation and analysis Keywords: jaw crusher; dual chamber; ADAMS; kinematics Stationary jaw crushers Sandvik jaw crushers are reliable, highperforming crushers built to optimize primary crushing applications in mines and quarries These tough crushers are delivered with everything you need for plugandplay installation and safety features to keep operators out of danger Backed up with a complete Reliability and Jaw crushers, Stationary Jaw crusher series SRP2015年5月5日 Jaw crusher kinematics simulation and analysis Jaw crusher is a kind of the relatively new compound pendulum jaw crusher, it has two crushing chamber and has an inverted crank rocker mechanism The design is mainly to meet the following requirements: 1, crusher capacity 3050t / h 2, the maximum grain size of the material feed 120mm 3, Jaw crusher kinematics simulation and analysis PDF

Analysis of the Single Toggle Jaw Crusher Kinematics

2023年10月21日 The work of Cao et al (2006) is a rare presentation of the kinematical analysis of the single toggle jaw crusher from first principles The paper states kinematical equationsEssa® JC1250 Jaw Crusher Our Essa JC1250 Jaw Crusher is small but strong We modelled it off the tried and tested larger JC2501 after extensive research and development For a compact crusher, our JC1250 can handle a high workload – up to 5 kg samples comfortably It has impressive throughput – up to 140 kg/hrFine Jaw Crushers 2014年9月1日 The main reason for this inefficiency is in the random distribution of forces on the particles inside the crusher With certain simplifications, the theoretical energy efficiency of comminution can be estimated to fall between 5 and 10 % (Legendre Zevenhoven, 2014) while the measured energy efficiency in actual comminution testing Assessing the energy efficiency of a jaw crusher ScienceDirect

Failure rate analysis of jaw crusher using Weibull model

2016年3月8日 The analysis included the failure intensity rate of the machinery fleet with allowance for the operation to date (610 thousand operating hours) The failure process of the machines in the 6 JournalofEngineering (2) Crank (4) Rocker (3) Coupler O2 O3 O4 O4 O1 O3 FY23 FY32 FY43 FZ43 FZ23 FZ32 FZ34 FY34 T3 T2 F3 F3 Figure3:Freebodydiagramsofthecrank,thecoupler,andtherocker (2) Crank Analysis of the Single Toggle Jaw Crusher Force 2023年10月25日 Appl Sci 2023, 13, 238 2 of 19 method (RSM), the predictive regression model of crusher performance was constructed The amplitude of vibration force was greatly decreased by increasing the mass Dynamics Analysis and Chaos Identification of

Improvement of Jaw Crusher Design by DEM FEA

2022年1月30日 In jaw crusher, another important analysis is breakage of the particle In particle breakage model, two types of approach are used widely which are Abt10 and Tavares model In this work, Abt10 model is used Abt10 model is developed by the Julius Kruttschnitt Mineral Research Centre (JKMRC) [9] The Abt10 particle breakage 2021年12月4日 Analysis for Cavity Shape of Single Toggle Jaw Crusher Xiaoqin Zhong, Xiaojian Niu, Qiqiang Ji et alInfluence of technological load on the stability of synchronous antiphase motion of the jaws of a vibratory crusher G Altshul, A Gouskov and G PanovkoThe Influence of the Structure of Double Toothed Roller Crusher on the Crushing Effect Open Access proceedings Journal of Physics: Conference 2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling A laboratory analysis was also conducted using Xray Fluorescence (XRF (PDF) SIZE REDUCTION BY CRUSHING METHODS

(PDF) Failure rate analysis of Jaw Crusher: a case study

2019年1月2日 The present paper deals with failure analysis of rock crusher and its critical components using total time on test (TTT)plot and other statistical tools TTTplot has proven to be a useful tool This paper presents the measurement and analysis of energy consumption of a laboratory jaw crusher during concrete recycling A method was developed to estimate the power requirements of a labscale jaw crusher Jaw crusher operates by compressing the feed material between a fixed and a moving jaw back and forth in an eccentric cyclic Energy consumption of a laboratory jaw crusher during 2017年5月1日 Abstract In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher Previously, jaw crushers were modelled in regard to certain aspects, for example, energy consumption (Legendre and Zevenhoven, 2014) or kinematics (Oduori et al, 2015) Approaches to date have been mainly property specificA fundamental model of an industrialscale jaw crusher

Analysis of the Single Toggle Jaw Crusher Force

According to Chinese jaw crusher manufacturer’s data [ 21 ], the PE 400 by 600 single toggle jaw crusher has 30 kW motor power and an input eccentric shaft speed of 275 rpm or 287979 radians per second Assuming that the input speed is constant, the input torque is found to be 10417 kNm2021年7月26日 The purpose of this project is to evaluate the kinematic and static force analysis of a single toggle jaw crusher that employs the simple technology of a four bar mechanism, and design a small scale mechanized jaw crusher for crushing the stones into aggregates This mechanism will help 23 JAW CRUSHER COMPONENTS Small Scale Mechanized Stone Crusher, Mechanical Design2022年7月13日 Different Types of Jaw Crusher: Jaw crusher can be divided into two according to the amplitude of motion of the moving face The different types of Jaw Crushers are Blake Type Jaw Crusher and Dodge Type Jaw Crusher II LITERATURE REVIEW Shyam SundarV has published a paper on "OPTIMUM DESIGN AND ANALYSIS OF February 2018, Volume 5, Issue 2 JETIR (ISSN 2349 5162)