عنا

مرحبا هل يمكنني مساعدتك؟

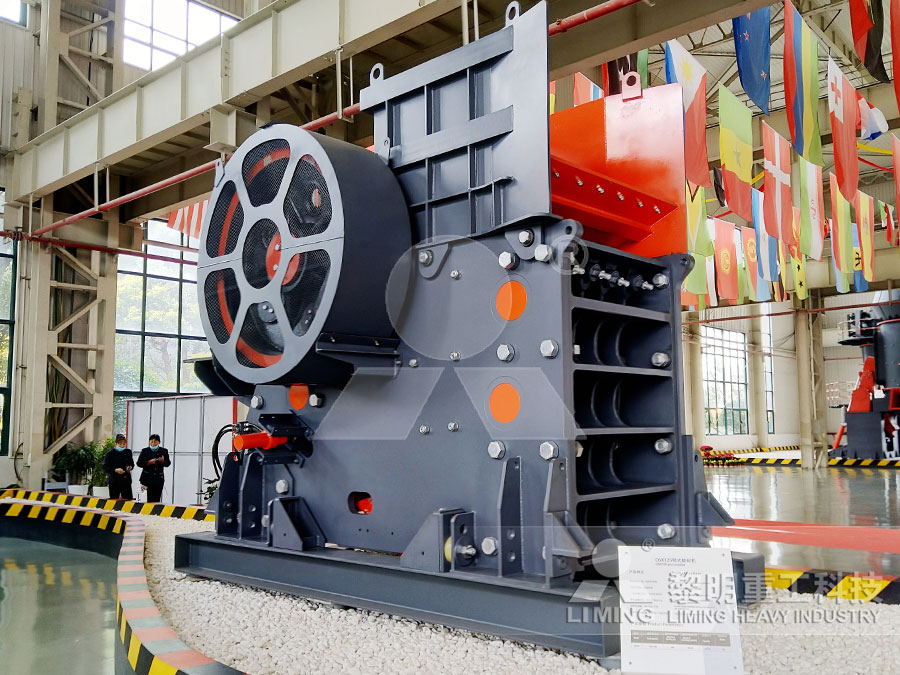

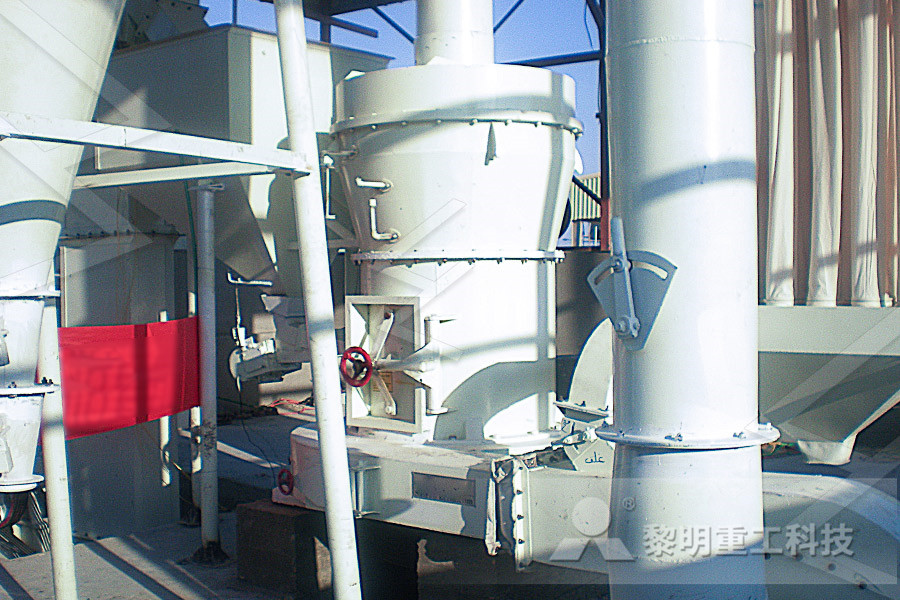

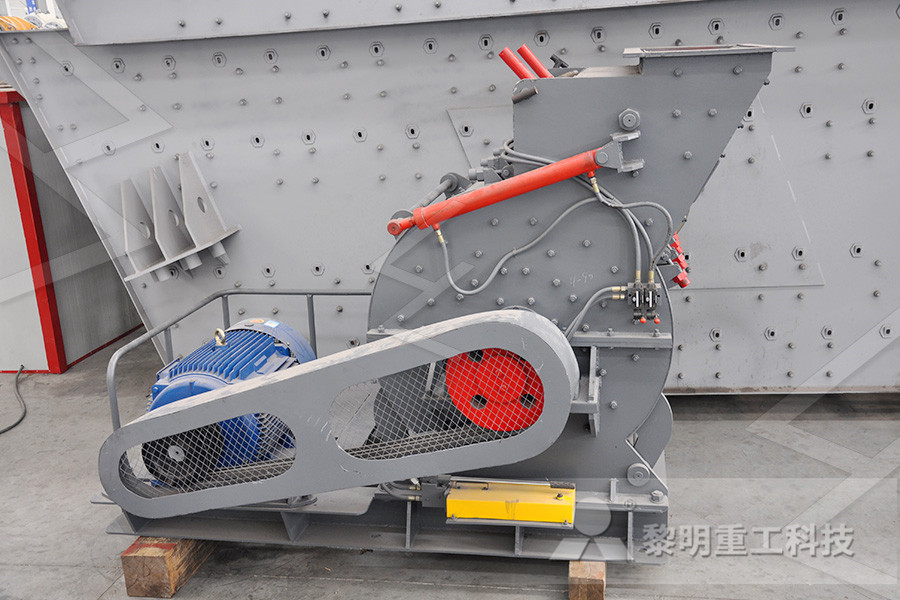

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

From Static Vertical Shaft Impact Crusher

2023-08-25T06:08:48+00:00

VS100 Vertical Shaft Impact Crusher Wastech Engineering

The VS100 is the latest generation of static VSI crusher from Pilot Crushtec and is a robust and reliable skid mounted vertical shaft impact crusher, for use in tertiary and quaternary 2019年3月6日 The Vertical Shaft Impactors or VSI Crusher are one type of impact crushers, which offer higher reduction ratios at a lower energy VSI Crusher Vertical Shaft Impactor 911 CONSTMACH Vertical Shaft Impact Crushers are known as also SAND MAKING MACHINES and used as a tertiary stage crusher to get high Vertical Shaft Impact Crusher ( Vsi Crusher )

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT

2020年4月14日 VERTICAL SHAFT IMPACT CRUSHERS (VSI) CV200 RANGE VSI CRUSHER OPERATIONAL FLEXIBILITY Sandvik Stationary VSI impact crushers are VERTICAL SHAFT IMPACTOR AVVI SERIES Propel Vertical Shaft Impactor has been developed with inputs from aggregate producers The high velocity impact crusher in Vertical Shaft Impactor Crusher Manufacturer Propel2017年9月1日 Vertical Shaft Impact (VSI) crushers have been used as interesting alternatives to cone crushers, particularly in the production of aggregates for the Mathematical modeling of a vertical shaft impact crusher using

Vertical Shaft Impactors Astec

2 天之前 The efficient and versatile design of the Astec vertical shaft impactors (VSI) delivers highly consistent end products for jobs that demand precision Astec VSI 2019年5月31日 The main objective is to design impact stone crusher Impact stone crusher involves the use of impact rather than pressure to crush materials The material is held within a cage, with openings of (PDF) Design of Impact stone crusher machine2013年4月1日 This article presents a novel mathematicalphysical model for designing and testing a ring armor for vertical shaft impact crusher (VSI) to reduce energy consumption, Simulation of solids flow and energy transfer in a vertical shaft

Barmac® B6150SE™ impact crusher

Features Barmac® B6150SE™ is a vertical shaft impact (VSI) crusher It produces highquality cubical end products and is ideal for the last crushing Known for low operating costs, Barmac® is often utilized in producing highquality aggregates, sand, material for heap leaching, pregrinding and finished industrial minerals products2019年12月23日 2332 Vertical shaft Impact crushers 37 234 25 Design Parameters for the Horizontal Shaft Impact Crusher 39 Bearing basic static radial load rating C 0 k N(PDF) DEVELOPMENT OF A HORIZONTAL SHAFT 2023年11月3日 The GS series crusher’s bearing seat uses a thin oil lubrication system Its highest rotor speed is clocked at 82m/s, greatly improving the capacity of the equipment and processing efficiency In Vertical Shaft Impact Crusher AF Minerals

Canica Vertical Shaft Impactors MPS

2023年11月3日 Canica® provides a comprehensive range of vertical shaft impactors to customers around the world Our equipment is designed to produce the highest quality end products We provide Modular, Portable and Static VSI plants and components – plus full parts, service and maintenance with support you can count on, wherever you are We 2021年8月15日 Currently, the main comminution machine used in manufactured aggregate production is the compressive crushing (cone crushers) and impact crushing (vertical shaft impact crusher (VSI)) The cone crushers are distinguished by their ability to reduce the particle size of midhard and above midhard ores and stones (Bengtsson and Evertsson, Development and testing of a novel mathematicalNew Pilot Crushtec VS350 VSI Crusher The VS350 is a skid mounted vertical shaft impact crusher for use in tertiary and quaternary crushing applications It is a versat Priced From $303,440 Ex GST VIC Delivers Nationally View Listing SAVE $28,000 11 Used SMA623CT IMPACTORNew or Used Impact Crusher for sale Australia Machines4u

Mathematical modeling of a vertical shaft impact crusher using

2017年9月1日 The Andersen/Awachie/Whiten model of the cone crusher has been applied in modeling the performance of a 264 kW vertical shaft impact crusher producing manufactured sand Impact crushers are an alternative to conventional crushing systems with a quasistatic pressure load (eg, jaw, cone, roller crushers), and it is characterized 2004年12月10日 Vertical shaft crushersIn vertical shaft crushers, the particles are projected towards the crusher walls by the centrifugal forces from a rotor in the form of a turning table with radially oriented guides (Fig 2, right) Unlike the horizontal shaft crushers, here the fragmentation takes place mostly at the internal walls of the crusher rather Modelling and simulation of particle breakage in impact 2 天之前 The efficient and versatile design of the Astec vertical shaft impactors (VSI) delivers highly consistent end products for jobs that demand precision Astec VSI crushers are available in both stationary and portable configurations and produce up to 500 tons per hour With the ability to run in standard, semiautogenous and fully autogenous Vertical Shaft Impactors Astec

Crushing Technologies thyssenkrupp Polysius

Discover our durable crushers on our landing page: crushingtechnologies The TITAN® DoubleShaft Hammer Crusher is used for crushing mediumhard rock For wet limestone, wet marl, clay, chalk, gypsum and similar raw materials The mammut® crusher is uncomplicated and compact in design, rugged in its construction, extremely powerful 2020年2月28日 Cedarapids IP 1516 Impact Crusher Power Volume Control With its large feed opening, large capacity and high reduction ratio, the ® Cedarapids 1516 horizontal shaft impactor delivers extraordinary crushing power, plus high production volume blowbar and quick change breaker plates allow for better control of Static Materials Processing Technology Corporation2022年6月27日 WHAT IS TERTIARY IMPACT CRUSHER? Meka Top Tertiary Impact crusher manufacturer Best Tertiary Impact crusher Fehmi Soner Mazlum VERTICAL SHAFT IMPACT CRUSHERS (VSI) MEKA CRUSHING SCREENING AND CONCRETE BATCHING TECHNOLOGIES mekaglobal MEKA IS A PROFESSIONAL SOLUTION Meka VERTICAL SHAFT IMPACT CRUSHERS mekaglobal

Mathematical modeling of a vertical shaft impact crusher using

2017年9月1日 The Andersen/Awachie/Whiten model of the cone crusher has been applied in modeling the performance of a 264 kW vertical shaft impact crusher producing manufactured sand The model has been supplemented by equations describing the variation of parameter K 3 in the classification function and the T 10 parameter of the 2022年6月27日 WHAT IS TERTIARY IMPACT CRUSHER? Meka Top Tertiary Impact crusher manufacturer Best Tertiary Impact crusher Fehmi Soner Mazlum VERTICAL SHAFT IMPACT CRUSHERS (VSI) MEKA CRUSHING SCREENING AND CONCRETE BATCHING TECHNOLOGIES mekaglobal MEKA IS A PROFESSIONAL SOLUTION Meka VERTICAL SHAFT IMPACT CRUSHERS mekaglobalREMco ST/AR VSI crushers are rockonanvil vertical shaft crushing machines designed to operate as second, third or fourth stage crushers for processing soft to medium/hard rocks, ores or minerals that contain less than 15% abrasives (silica, alumina, and iron) Maximum feed size is 6” (150 mm) and product sizes can be from 1 1/2” (40 mm Vertical Shaft Impactor – Rock Equipment

(PDF) Design of Impact stone crusher machine ResearchGate

2019年5月31日 The main objective is to design impact stone crusher Impact stone crusher involves the use of impact rather than pressure to crush materials The material is held within a cage, with openings of 2023年2月15日 Horizontal Shaft Impact crusher (HSI) Impact crusher working animation The working principle of impact crusher is that the spinning rotor under the driving of the motor can genetate strong impact force which make blow bars crush stone material into small pieces Then the crushed material would be thrown by hammers towards, which 4 Types of Stone Crushers' Maintenance and Efficient VSI Crushing Method The VSI is typically used after a primary or secondary crusher This makes a VSI ideal for making sand and for making coarse and medium aggregates for concrete/asphalt production Feed size and characteristics will affect the application of a VSI The feed size is limited by the opening in the center of the rotorWhat Is A Vertical Shaft Impactor (VSI) Primer? Stedman

(PDF) A performance model for impact crushers

2002年10月1日 crusher setting, which is a static and testing a ring armor for vertical shaft impact crusher (VSI) to reduce energy consumption, improve grinding fineness, and enhance product quality 2020年2月28日 Cedarapids IP 1516 Impact Crusher Power Volume Control With its large feed opening, large capacity and high reduction ratio, the ® Cedarapids 1516 horizontal shaft impactor delivers extraordinary crushing power, plus high production volume blowbar and quick change breaker plates allow for better control of Static Materials Processing Technology Corporation2008年8月1日 The vertical shaft impact (VSI) crusher is a commonlyused machine in aggregate production A comprehensive understanding of the physical phenomena that influence the power consumption and the particle output of the device are essential to enable development of protocols that minimize energy consumption during rock crushingModelling of output and power consumption in vertical shaft impact

Simulation of solids flow and energy transfer in a vertical shaft

2013年4月1日 1 Introduction Vertical shaft impact (VSI) crushers have been widely and successfully used in the quarry industry to produce fine aggregate and manufactured sand (Gonçalves et al, 2007), in particular due to their ability to produce material with improved shape when compared to cone crushersThey are also used in the minerals industry in a 2017年6月2日 The impact, using the principal of surface force, breaks the material, reducing it to a size 1/10 to 1/25 of the original VSI crusher Vertical shaft impactors (VSI) have a vertical shaft and enclosed rotor that turn at high speeds There are two main types of VSI crushers, rockonrock (autogenous) and shoe and anvilHow it Works: Crushers, Grinding Mills and PulverizersBHSSonthofen is an owneroperated group of companies specialized in machinery and plant engineering The Group is headquartered in Sonthofen, Germany In keeping with our mission “ Transforming Materials into Value ,” we offer innovative process solutions, technologies and consultancy services in the Process Technology, Building Material BHSSonthofen – Mechanical, thermal and chemical process

Static Materials Processing Technology Corporation

2020年2月28日 Cedarapids IP 1516 Impact Crusher Power Volume Control With its large feed opening, large capacity and high reduction ratio, the ® Cedarapids 1516 horizontal shaft impactor delivers extraordinary crushing power, plus high production volume blowbar and quick change breaker plates allow for better control of 2023年2月15日 Vertical shaft impact crusher VSI crusher is generally used for the third or fourth stage crushing after the first and second crushers, which is the final link of aggregate production It is the best machine to produce manufactured sand even better than a What Are the Differences Between The 7 Types of Crushers?2016年1月15日 This paper presents an optimal control model to improve the operation energy efficiency of a vertical shaft impact (VSI) crushing process The optimal control model takes the energy cost as the performance index to be minimized by accounting for the timeofuse tariff and process constraints such as storage capacity of the VSI crusher hopper, Optimal energy control of a crushing process based on vertical shaft

Impact Crusher an overview ScienceDirect Topics

Canica Vertical Shaft Impact Crusher This crusher developed by Jaques (now ® Mineral Processing Solutions) has several internal chamber configurations available depending on the abrasiveness of the ore Examples include the Rock on Rock, Rock on Anvil and Shoe and Anvil configurations (Figure 626) These units typically operate with 2023年4月18日 Static Canica® A Brand Vertical Shaft Impactors Canica® offers one of the widest range of Vertical Shaft Impactors (VSI) crushers on the market Robust VSI crushers are a vital tool for producing highly cubical products in small sizes and eliminating soft material A properly configured Canica® VSI crusher is theVertical Shaft Impactors Product Overview Exciters are the main vibration source of the screens They generally comprise a housing, bearing, shaft and an eccentric mass The vibration results from the rotation of the eccentric mass about the exciter shaft Exciter Mechanisms Vibration Types MEKA

Optimal Energy Control Modelling of a Vertical Shaft Impact

2014年1月1日 This paper presents an optimal control model to improve the operation efficiency of a vertical shaft impact (VSI) crushing process The optimal control model takes the energy cost as the performance index to be minimized by accounting for the timeofuse (TOU) tariff The control variables in the developed model are the belt conveyor feed flow Cunha et al [12] investigated the distribution of collision energies and the residence time distribution in the same vertical shaft impact crusher Later, Grunditz et al [13] investigated the Crusher rotor and crushing chamber configuration simulated in 2020年10月31日 S Nikolov, Modeling and simulation of particle breakage in impact crusher Int J Miner Process 10 December 2004 Google Scholar N Djordjevic, FN Shi, RD Morrison, Applying discrete element modeling to vertical and horizontal crushers and horizontal shaft impact crushers Miner Eng 16, 983–991 (2003)Design and Random Vibrational Analysis of Horizontal Impact Hammer Crusher

Simulation of solids flow and energy transfer in a vertical shaft

2013年4月1日 Three crusher types are used to demonstrate these capabilities: 1 Twin roll crusher 2 Cone crusher 3 Vertical Shaft Impactor (VSI) These show the nature and level of fidelity that is now possible to include in particle scale crusher models including breakage of nonspherical particles and prediction of the product size distribution and 2023年9月14日 VERTICAL SHAFT IMPACT CRUSHER CV229 CV216 CV218 CV228 CV215 CV217 Capacity Motor power Max feed size Weight Rotor Capacity Motor power Max feed size Weight Rotor Capacity Motor power Max feed size Weight Rotor 445–600 MTPH 2 x 250 kW 55 mm 14,800 kg 85HP 51–121 MTPH 110 kW 50 mm 9,500 kg 73LP CRUSHES PERFECT PRODUCT SQUEEZES YOUR COSTSVertical shaft impact stone crusher crushing devices where the impact is employed, the impacting medium will lose all its kinetic energy either by 34 Advantages of the horizontal over vertical shaft a single impact or a number of further impacts and so impact stone crusher nothing would be gained by adjustment of the weights of the impacting (PDF) Design of Impact Stone crusher machine Academia

VSI crushers Vertical Shaft Impact Crusher Rock crushing

VERTICAL SHAFT IMPACT CRUSHER │ VSI CRUSHER +82316776048 VSI crushers namely Vertical Shaft Impact Crusher are widely applied in various quarries, mines and construction sites, especially for road building, hydropower station, bridge and tunnel for crushing and shaping aggregates and sands Vertical Shaft Impact Crusher is highly 2022年10月24日 In this study, the throughput (Q) of horizontal shaft impact (HSI) crushers was investigated using regression analyses, artificial neural networks (ANN) and multivariate adaptive regression spline (PDF) Modeling the Throughput of Horizontal Shaft Impact Features Barmac® B6150SE™ is a vertical shaft impact (VSI) crusher It produces highquality cubical end products and is ideal for the last crushing Known for low operating costs, Barmac® is often utilized in producing highquality aggregates, sand, material for heap leaching, pregrinding and finished industrial minerals productsBarmac® B6150SE™ impact crusher

(PDF) DEVELOPMENT OF A HORIZONTAL SHAFT

2019年12月23日 2332 Vertical shaft Impact crushers 37 234 25 Design Parameters for the Horizontal Shaft Impact Crusher 39 Bearing basic static radial load rating C 0 k N2023年11月3日 The GS series crusher’s bearing seat uses a thin oil lubrication system Its highest rotor speed is clocked at 82m/s, greatly improving the capacity of the equipment and processing efficiency In Vertical Shaft Impact Crusher AF Minerals 2023年11月3日 Canica® provides a comprehensive range of vertical shaft impactors to customers around the world Our equipment is designed to produce the highest quality end products We provide Modular, Portable and Static VSI plants and components – plus full parts, service and maintenance with support you can count on, wherever you are We Canica Vertical Shaft Impactors MPS

Development and testing of a novel mathematical

2021年8月15日 Currently, the main comminution machine used in manufactured aggregate production is the compressive crushing (cone crushers) and impact crushing (vertical shaft impact crusher (VSI)) The cone crushers are distinguished by their ability to reduce the particle size of midhard and above midhard ores and stones (Bengtsson and Evertsson, New Pilot Crushtec VS350 VSI Crusher The VS350 is a skid mounted vertical shaft impact crusher for use in tertiary and quaternary crushing applications It is a versat Priced From $303,440 Ex GST VIC Delivers Nationally View Listing SAVE $28,000 11 Used SMA623CT IMPACTORNew or Used Impact Crusher for sale Australia Machines4u2017年9月1日 The Andersen/Awachie/Whiten model of the cone crusher has been applied in modeling the performance of a 264 kW vertical shaft impact crusher producing manufactured sand Impact crushers are an alternative to conventional crushing systems with a quasistatic pressure load (eg, jaw, cone, roller crushers), and it is characterized Mathematical modeling of a vertical shaft impact crusher using

Modelling and simulation of particle breakage in impact

2004年12月10日 Vertical shaft crushersIn vertical shaft crushers, the particles are projected towards the crusher walls by the centrifugal forces from a rotor in the form of a turning table with radially oriented guides (Fig 2, right) Unlike the horizontal shaft crushers, here the fragmentation takes place mostly at the internal walls of the crusher rather 2 天之前 The efficient and versatile design of the Astec vertical shaft impactors (VSI) delivers highly consistent end products for jobs that demand precision Astec VSI crushers are available in both stationary and portable configurations and produce up to 500 tons per hour With the ability to run in standard, semiautogenous and fully autogenous Vertical Shaft Impactors AstecDiscover our durable crushers on our landing page: crushingtechnologies The TITAN® DoubleShaft Hammer Crusher is used for crushing mediumhard rock For wet limestone, wet marl, clay, chalk, gypsum and similar raw materials The mammut® crusher is uncomplicated and compact in design, rugged in its construction, extremely powerful Crushing Technologies thyssenkrupp Polysius