عنا

مرحبا هل يمكنني مساعدتك؟

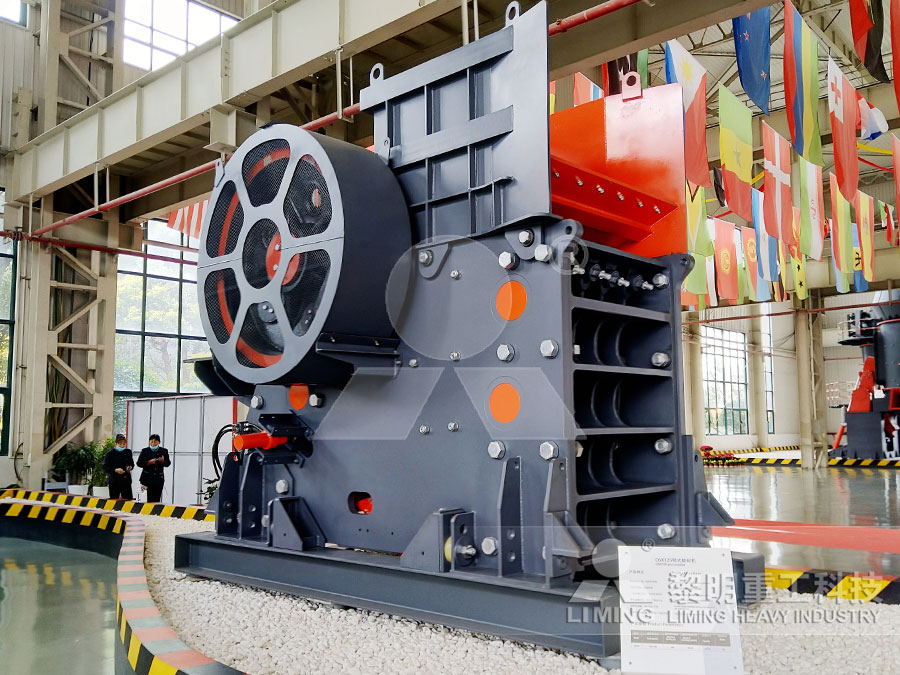

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

conical ball mills versus tubular ball mill

2023-10-21T10:10:14+00:00

Conical Ball Mill CostEffective Conical Ball Mill

Conical Ball Mill is a kind of ball mill commonly used in beneficiation production This machine has changed the original structure of the mill to integrate the machine body and chassis It can be installed once and placed on the foundation plane, and the main Conical ball mills versus tubular ball mill Advantages and disadvantages of ball mill cement grinding vertical roller mills versus ball mills rucem a decided advantage over a ball mill conical ball mills versus tubular ball mill buerotekturA conical ball mill is a type of ball mill that has a conicalshaped drum on one end and a cylindricalshaped drum on the other end The material to be ground is fed into the How to Choose the Right Types of Ball Mill for Your

conical ball mills versus tubular ball mill

2019年4月22日 Differences Between Tubular Mills And Ball Mills Conical ball mills versus tubular ball millConical ball mills versus tubular ball mill offers 161 telescopic ball screw 2016年1月1日 The design of different types of Tubular Ball Mills used for size reduction of crushed RunofMine ores is described in some detail followed by descriptions and Tubular Ball Mills ScienceDirectConical Ball Mills Versus Tubular Ball Mill Cone Ball Mill Conical Ball Mill Pyb pydpyz cone crusher conical crusher 1introduction of widely used mill concrete conical crusher this Conical Ball Mills Versus Tubular Ball Mill

Conical Ball Mills Benefits Advantages: Hardinge

2015年3月30日 It has been found, by comparing the operation of Conical Mills with cylindrical tube mills in the grinding of ore and limestone, that with the same ball load in both types of mills, the cylindrical mill will consume 2021年9月17日 1 Tubular ball mill introduction Tubular ball mill introduction, the usual objective of reducing the size of runof mine ore pieces is to separate the mineral of Tubular ball mill Henan Deya Machinery Co, LtdTubular ball mills are a type of grinding mill used for processing materials in bulk, featuring a horizontal cylindrical shell and multiple chambers for processing different materials Tubular Ball Mill Ball Mill For Sale Low Energy Consumption Ball

between tubular mills and ball mills ltpilateses

Conical Ball Mills Versus Tubular Ball Mill Ball Mill Ball Mills An Overview Sciencedirect Topics, Conical ball mills differ in mill body construction which is composed of two cones 2019年7月28日 A co mill (or conical mill) is a machine used to reduce the size of pharmaceutical material in to a uniform measure it is widely used in Pharma sales@senieer +86; An illustration of a Co Mill, Conical mill, Comill, Cone Mill: 1992年1月1日 It has been found that a change in density of 26 to 29 (an increase of density of 115%) gives a 15% increase in mill power for these conical mills, for Pb = 775 Inserting p51 = 26, Pb = 775 and solving for fc gives 0445, and using the estimate for c, f ~ 10 Thus it appears that the powder in the mill is circulating in about the same Mill power for conical (Hardinge) type ball mills ScienceDirect

Calculate Ball Mill Grinding Capacity 911

2015年10月15日 A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill 2022年11月30日 The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size The large balls tend to break down the coarse feed materials and the smaller balls help to form fine product by reducing void spaces between the balls Ball mills grind material by impact and attritionBall Mill: Operating principles, components, Uses, 2020年9月22日 The best ball mills, however, enable you to achieve the desired product quality quickly and e ciently, with minimum energy expenditure That’s what the ball mill is designed to do – with the added benefit of high flexibility You decide whether to operate the mill in open or closed circuit, with or without a pregrinderBall mill Superior cement quality, More fl exibility, higher

What Are the Differences between Dry and Wet Type Ball Mill?

2023年2月15日 The water can wash away the fine particles in time to avoid overgrinding The wet ball mill has a low noise, and low environmental pollution The wet ball mill has a simple transportation device with less auxiliary equipment, so the investment is about 5%10% lower than that of a dry ball mill The grinding particle size is fine and uniform2020年3月10日 Overview of Ball Mills As shown in the adjacent image, a ball mill is a type grinding machine that uses balls to grind and remove material It consists of a hollow compartment that rotates along a horizontal or vertical axis It’s called a “ball mill” because it’s literally filled with balls Materials are added to the ball mill, at What Is a Ball Mill? Blog Posts OneMonroe2016年3月15日 Ball Mill Crushing by tubemills were first introduced into the crushing departments of cyanide plants when it was found that for crushing finer than 30mesh other types of crushing machinery were not efficient In order to crush with one pass, these mills were made 18 to 22 ft (55 to 67 m) in length Pebbles were used as a grinding medium Ball Mill Crushing 911 Metallurgist

What Are the Parts of a Cement Mills? Cement Ball Mill

2023年8月23日 After exiting the cement kiln, the clinker is cooled and stored To produce cement, clinker is mixed with a small amount of gypsum and other additives, such as pozzolans or slag This mixture is then ground in the cement ball mill The grinding process involves passing the clinker and additives through the rotating drum of the ball mill, where 2017年7月3日 Rods in place weigh approximately 400 pounds per cu ft and balls in place approximately 300 pounds per cu ft Thus, quantitatively, less material can progress through the voids in the rod mill grinding Ball Mills vs Rod Mills 911 MetallurgistA conical ball mill is a type of ball mill that has a conicalshaped drum on one end and a cylindricalshaped drum on the other end The material to be ground is fed into the cylindrical drum, and as the drum rotates, the material is ground and discharged through the conical end Conical ball mills are suitable for coarse grinding and can How to Choose the Right Types of Ball Mill for Your

chapter tubular ball mills

Conical Ball Mills Versus Tubular Ball MillChapter 7 Tubular Ball Mills sciencedirect Chapter 7 Tubular Ball Mills Scribd Tubular Ball Mills 7 A mill of this type is the Hardinge mill where the discharge end of the mill shell is conical in The design of different types of Tubular Ball Mills used for size reduction of crushed Run of Mine ores is described in some detail 2015年12月22日 Hardinge Conical Ball Mills are used to do the work of any combination of the above machines and will produce the desired results, depending upon the size and type of mill used Hardinge Conical Ball Mill Diameter: 45 ft Length: 16 in Shell speed: 29 rpm 1/2 in steel plate sell Wet grind ball mill Access man hole Comes with: 20 hp Hardinge Conical Ball Mill 911 Metallurgist2017年8月29日 pirical formulae for wet rod mills and wet and dry ball mills, where the diameter occurs as DO4 The formula contains in accordance with above explana tion the factor Os (fraction of critical speed) and the filling rate of the grind ing media charge It is important to stress, however, that a simultaneous slippagefree millTUMBLING MILL MECHANICS Springer

Tubular Ball Mill Ball Mill For Sale Low Energy Consumption Ball

Tubular ball mill is the key equipment for crushing materials after they are crushed Ball mills are widely used in the production industries of cement, silicate products, new building materials, refractory materials, fertilizers, ferrous and nonferrous metal beneficiation, and glass ceramics, for dry or wet grinding of various ores and other grindable materials2015年4月1日 1 Introduction Airswept raw meal ball mills introduced by the cement mill manufacturers ® (Smidth, 2002), Polysius ® (Polysius, 2002) and KHD Humboldt Wedag® are the most commonly used onesKHD Humboldt Wedag® manufactured fully airswept raw meal mills which have two compartments used for drying and grinding processesOptimization of a fully airswept dry grinding cement raw meal ball 2017年3月8日 Considering the amount of copper contained in the two products, that from the Hardinge mill has 718 per cent, of its total coppercontent in the material through 20 and on 200 mesh, as compared with 3434 per cent, for the Chilean mill This result will materially affect the amount and cost of recovery As to the amount of water required Hardinge Conical Mill Grinding Efficiency Compared 911

Grinding Mills Common Types 911 Metallurgist

2016年11月7日 Tube mills Rod mills Ρebble mills Ball mill The term “ball mill” is usually applied to a mill in which the grinding media are bodies of spherical form (“balls”) and in which the length of the mill is of the same order as the diameter of the mill body; in rough figures the length is, say, one to three times the diameter of the mill 2016年1月1日 Tubular tumbling mills loaded with rods as the grinding media are used for primary grinding of rocks and minerals Rods are placed parallel to the length of the mill, their length being about 150 mm shorter than the inside length of mills The grinding action for size reduction of particles is almost similar to ball mills, but in this case the Tubular Rod Mills ScienceDirect2012年4月1日 Assessment of mills to established fatigue design rules A model of the mill investigated in this study was developed using the original design geometry during the auditing phase of the project The charge load used for design was 45% total charge with 40% ball charge, as is commonly used in mill specifications for the maximum structural loadFatigue design of mills ScienceDirect

Ball Mill Products Ball Mill For Sale Ball Mill Equipment

Buy Ball Mill Products from a professional manufacturer Ball mill for industrial materials, cement, and mineral grinding Tubular ball mill Power(KW): 45~1000 (r/min): 172~305 Conical Ball Mills Motor Power / (KW): 4~400 Feed Particle Size / (mm): 0~35 Ball Load/ (KG): 600~39000 Overflow Ball Mill Cylinder Diameter (mm): 900 Strong Commonality Ball mills manufactured by AGICO are applicable to all industrial pulverizing fields They can handle metal ore, nonmetal ore, and sintering materials with various hardness Our ball mills have a wide range of applications, extensively applied in medium or largescale productionIndustrial Application Of Ball Mill AGICO2008年9月1日 The experiments were performed on a tubular ball mill of a 250 MW power plant unit (see Fig 1)The mill has a diameter of 32 m and a length of 47 m, and driven by a motor (YTM5006) The nominal revolutions per minute (rpm) of this mill was 1842, and the mill power draft 710 KWThe mill was operated with a combination of three different Experimental investigation of vibration signal of an industrial tubular

Tubular ball mill Henan Deya Machinery Co, Ltd

2021年9月17日 As a general rule: 1 For overflow ball mills the charge should not exceed 45% of the mill volume, 2 For grate discharge mills the charge should occupy about 50% of the mill volume 33 Ball Size at Initial Ball Charge Ball sizes commercially available for charging in grinding mills range from 10 to 150 mmObjectives At the end of this lesson students should be able to: Explain the grinding process Distinguish between crushing and grinding Compare and contrast different type of equipment and their components used for grinding Identify key variables for process control Design features of grinding equipment (SAG, BALL and ROD MILLS)AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator 2023年11月3日 Types of mechanical mills include hammer mills, ball mills, pin mills and roller mills This variety of mechanical machinery can be used to effectively pulverize powders, but comes with a host of limitations and disadvantages First and foremost mechanical milling will not allow for reducing particles to the smaller sizesMechanical Milling vs Jet Milling: Learn the Difference

End Mill Comparison Guide MatterHackers

2020年2月18日 BallNose End Mills Ballnose end mills have a domeshaped tip These excel at highdetail contours like relief artwork or mold and die making, but have what is known as “scalloping” Since the tip of the end mill is round, having a perfectly flat surface is a challenging feat and will take many more passes than a simple fishtail to smooth 2021年5月11日 Construction of Ball Mill The ball mill consists of a hollow metal cylinder mounted on a shaft and rotating about its horizontal axis The cylinder can be made of metal, porcelain, or rubber Inside the cylinder Construction and Working of Ball Mill Solution Milling Ball Mills; Impact Mill; Spiral Flow Jet Mill; Opposed Jet Mill Opposed jet mills are a type of microniser used for the superfine grinding of a wide range of materials where other forms of mill are unsuitable, particularly in cases where the feed material is hard, already relatively fine, has a low melting point or where high purity products, without Conical Ball Mills Versus Tubular Ball Mill

Ball Mill vs Rod Mill: Which is the Best for Your Mining

One of the advantages of a rod mill is that it can handle a higher capacity than a ball mill of the same size Additionally, the grinding medium in a rod mill is more uniform than that in a ball mill, and this can be beneficial for certain materials Rod mills are also relatively lowmaintenance, making them a costeffective option for many 2018年11月2日 Planetary Ball Mills: They are a form of vertical ball mills used for testing laboratories They have smaller chamber balls and a limited capacity It is only available in smaller sizes so as to ensure that it can be comfortably placed on tables or benches Ball mill manufacturers of India are increasingly experimenting with the form, structure What are the Different Types of Ball Mills? Techno Designschapter tubular ball mills Chapter 7 Tubular Ball Mills ScienceDirect Thus, the medium could be steel or cast iron balls when the mill is designated as a ball mill, or it could be steel rods where the mill is known as a rod mill When no grinding medium is charged it is known as an autogenous millchapter 7 tubular ball mills

A Comprehensive Guide to Ball Mill Manual ball mills supplier

A ball mill is a crucial piece of machinery used in grinding and mixing materials in various industries It works by rotating a cylinder with steel or ceramic balls, causing the balls to fall back into the cylinder and onto the material to be ground Ball mills are used extensively in the mining, construction, chemical, and pharmaceutical 2023年11月3日 Small Ball Mills – Canada We sell Small Ball Mills from 2′ to 6’ (600 mm X 1800 mm) in diameter and as long as 10″ (3000 mm) in length The mills are manufactured using a flanged mild steel shell, cast heads, overflow discharge, removable man door, spur type ring gear, pinion gear assembly with spherical roller bearings, replaceable roller Small Ball Mill 911 Metallurgist2022年4月1日 Mineral liberation analyser (MLA) suggested that the liberation of iron from gangue was through grinding in the ceramicmedium stirred mill Four NEUM850 ceramicmedium stirred mills superseded the ball mills of second and third stage in the Aoshan concentrator, and the grinding unit consumption decreased by 4838%The first attempt of applying ceramic balls in industrial tumbling mill

Laboratory Mixer Mill MM 400 RETSCH

Mixer Mill MM 400 The Mixer Mill MM 400 is a true multipurpose mill designed for dry, wet and cryogenic grinding of small volumes up to 2 x 20 ml It mixes and homogenizes powders and suspensions with a frequency of 30 Hz within seconds – unbeatably fast and easy to operate The compact benchtop unit is suitable for classic homogenization Mills versus ball mills Know More Ball mill Wikipedia A ball mill, a type of grinder, is a cylindrical device used in grinding or mixing materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including differences between tubular mills and ball mills2019年7月28日 A co mill (or conical mill) is a machine used to reduce the size of pharmaceutical material in to a uniform measure it is widely used in Pharma sales@senieer +86; An illustration of a Co Mill, Conical mill, Comill, Cone Mill:

Mill power for conical (Hardinge) type ball mills ScienceDirect

1992年1月1日 It has been found that a change in density of 26 to 29 (an increase of density of 115%) gives a 15% increase in mill power for these conical mills, for Pb = 775 Inserting p51 = 26, Pb = 775 and solving for fc gives 0445, and using the estimate for c, f ~ 10 Thus it appears that the powder in the mill is circulating in about the same 2015年10月15日 A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill Calculate Ball Mill Grinding Capacity 911 2022年11月30日 The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size The large balls tend to break down the coarse feed materials and the smaller balls help to form fine product by reducing void spaces between the balls Ball mills grind material by impact and attritionBall Mill: Operating principles, components, Uses,

Ball mill Superior cement quality, More fl exibility, higher

2020年9月22日 The best ball mills, however, enable you to achieve the desired product quality quickly and e ciently, with minimum energy expenditure That’s what the ball mill is designed to do – with the added benefit of high flexibility You decide whether to operate the mill in open or closed circuit, with or without a pregrinder2023年2月15日 The water can wash away the fine particles in time to avoid overgrinding The wet ball mill has a low noise, and low environmental pollution The wet ball mill has a simple transportation device with less auxiliary equipment, so the investment is about 5%10% lower than that of a dry ball mill The grinding particle size is fine and uniformWhat Are the Differences between Dry and Wet Type Ball Mill?2020年3月10日 Overview of Ball Mills As shown in the adjacent image, a ball mill is a type grinding machine that uses balls to grind and remove material It consists of a hollow compartment that rotates along a horizontal or vertical axis It’s called a “ball mill” because it’s literally filled with balls Materials are added to the ball mill, at What Is a Ball Mill? Blog Posts OneMonroe

Ball Mill Crushing 911 Metallurgist

2016年3月15日 Ball Mill Crushing by tubemills were first introduced into the crushing departments of cyanide plants when it was found that for crushing finer than 30mesh other types of crushing machinery were not efficient In order to crush with one pass, these mills were made 18 to 22 ft (55 to 67 m) in length Pebbles were used as a grinding medium 2023年8月23日 After exiting the cement kiln, the clinker is cooled and stored To produce cement, clinker is mixed with a small amount of gypsum and other additives, such as pozzolans or slag This mixture is then ground in the cement ball mill The grinding process involves passing the clinker and additives through the rotating drum of the ball mill, where What Are the Parts of a Cement Mills? Cement Ball Mill