عنا

مرحبا هل يمكنني مساعدتك؟

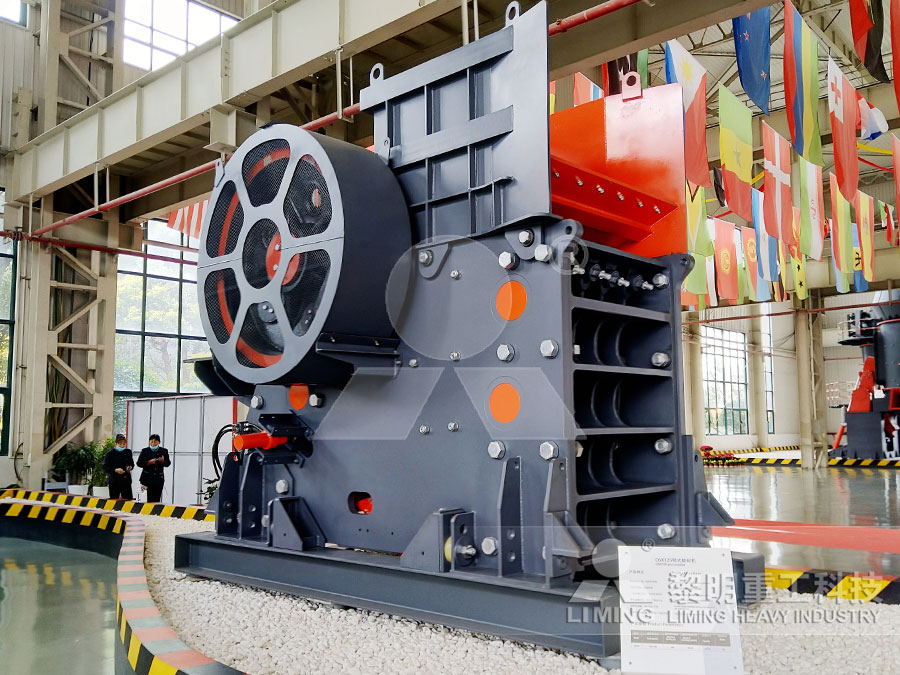

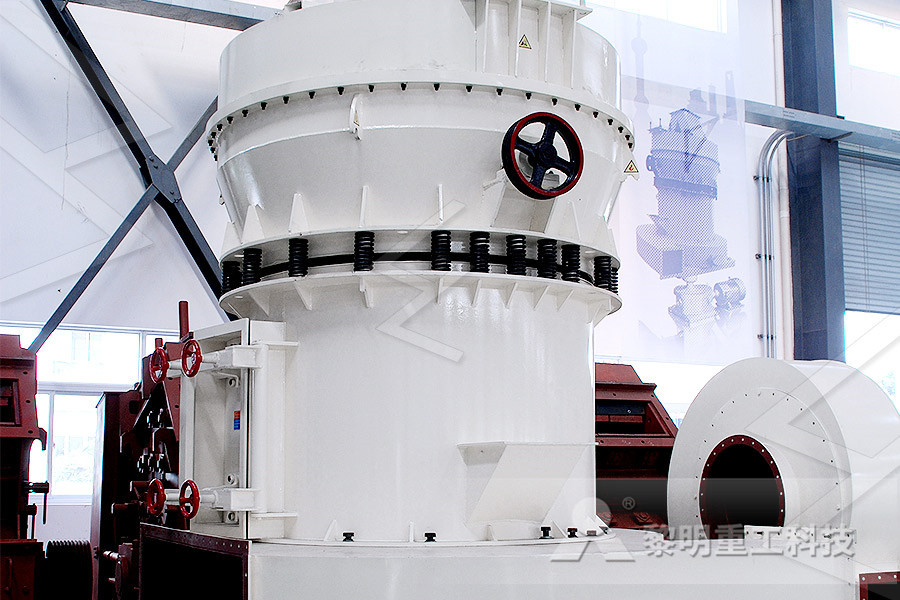

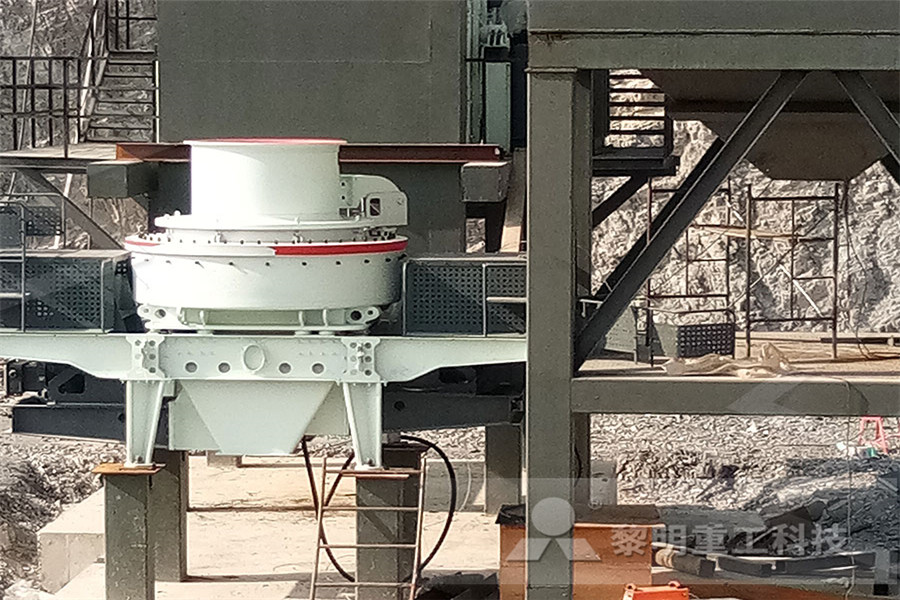

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

ball mill design calculation pdf

2023-11-16T04:11:25+00:00

Ball Mill Design/Power Calculation DESIGN AND ANALYSIS OF BALL MILL

2015年6月19日 Today, much of on mill designing is finish by radios, power models and another These will a goods backtobasics exercises for those willingness to understand 2018年12月9日 Define and calculate the classification system efficiency of a ball mill circuit Define and calculate the grinding efficiency of the ball mill in a ball mill circuit MODULE #5: FUNCTIONAL PERFOMANCE OF BALL 2020年2月26日 PDF Owing to the lack of effective energy consumption models of ball mills in the ceramic industry, a calculation model to (PDF) Calculation method and its application for

(PDF) DESIGN AND FABRICATION OF MINI BALL

2016年5月30日 PDF This project is to design and fabricate a mini ball mill that can grind the solid state of raw materials into fine powder2018年4月7日 Ball Mill Design/Power Calculation Small Ball Mill Capacity Sizing Table Ball Mill Design/Power CalculationBall Mill Design Calculations How to 911 2016年4月25日 PDF This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder The Find, read and cite all the research(PDF) DESIGN AND FABRICATION OF MINI BALL

ResearchGate Find and share research

2012年6月1日 (PDF) Grinding in Ball Mills: Modeling and Process Control PDF The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in2023年10月19日 Ball Mill Calculations Free download as Excel Spreadsheet (xls), PDF File (pdf), Text File (txt) or view presentation slides online ball mill calculations Chimney Design Calc (1) Ball Mill Calculations PDF Mill (Grinding)2016年4月25日 To ensure the stability of the mini ball mill, a ball mill base is design and fabricate to withstand the weight of the rotating jar, motor and gears After a few hours, stop the mini ball mill and (PDF) DESIGN AND FABRICATION OF MINI BALL

ResearchGate Find and share research

2012年6月1日 ResearchGate Find and share research2018年10月9日 1 Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the discrete element method, we must first be able to reproduce the balls’ motion in the ball mill using simulations Kano et al8) have made it clear that it is possible to reproduce the ball motion when the solid material isDesign Method of Ball Mill by Discrete Element MethodLaboratory Ball Mill By C C Ugwuegbu, A I Ogbonna, U S Ikele, J U Anaele, U P Ochieze AOnwuegbuchulam Federal University of Technology Abstract In this study, a 5 kg laboratory ball mill has been designed, constructed, and its performance analysed This was achieved by using Bond’s equation to calculate the specific andDesign, Construction and Performance Analysis of a 5

Grinding Mill Computer Model AusIMM

2021年6月24日 35 Pebble Mill Design This reverts to the Morgärdshammar method and is similar to the AM calculation 36 Tower Mill The tower mill calculation is based on the ball mill design sheet, but is simplified in that the mill design section is omitted A simple tower mill factor of 70% allows the mill power to be estimated MILLCALCv2a 5 19/02/年8月30日 V — Effective volume of ball mill, m3; G2 — Material less than 0074mm in product accounts for the percentage of total material, %; G1 — Material less than 0074mm in ore feeding accounts for 0074mm in the percentage of the total material, %; q’m — Unit productivity calculated according to the new generation grade (0074mm), t/(m3h) The Ball Mill Parameter Selection Calculation JXSC MachineQuantum Nanostructures (QDs): An Overview D Sumanth Kumar, HM Mahesh, in Synthesis of Inorganic Nanomaterials, 2018 3611 Ball Milling A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball Ball Mill an overview ScienceDirect Topics

Ball Mill Design PDF Mill (Grinding) Celsius Scribd

2016年5月18日 Bag Filter Capacity = 41810064 M3/Hour At 70 Degree Celsius Taking 10 % Extra for Fan = 45991071 M3/Hour At 70 Degree Celsius Taking a Pressure drop of 150 200 mm of hg Hence bag filter fan =45991071 M3/Hour At 2017年2月13日 CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′ High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volumeBall Mills 911 Metallurgist2021年7月27日 Considering that worn balls in an industrial mill charge constitute about 15 to 40 percent and that the highest difference in breakage rate observed being nine percent for purely one shape charge; it is very doubtful whether it is worthwhile in attempting to develop techniques for removing worn balls from the millEFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL

Calculate Ball Mill Grinding Capacity 911

2015年10月15日 A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill 2014年11月13日 The types of ball mills: batch ball mill and continuous ball mill with different grinding media and different design depend on the nature of the input material and the nature of the output which I need We Ball Mill [PDF Document]2023年11月1日 You also need a rod mill work index to design a ball mill operating on a coarse feed, above about 4 mm Q1: You design for a typical percentage of critical speed, usually 75% of critical Then you iterate the mill diameter using a Morrell Cmodel or equation to get the RPM that corresponds to 75% for that mill diameterHow to design a Ball Mill Grinding Classification Circuits

Ball Mill Loading Dry Milling Paul O Abbe

The starting point for ball mill media and solids charging generally starts as follows: 50% media charge Assuming 26% void space between spherical balls (nonspherical, irregularly shaped and mixedsize media will increase or decrease the free space) 50% x 26% = 13% free space Add to this another 10%15% above the ball charge for total of 23% 2020年11月16日 The balls to powder ratio (BPR) and powder type were investigated in relation to the particle size The study showed that the combination of the BPR and powder type affects the particle size result The optimum of BPR at 12 with the number of balls is 60 pieces, and the filling rate is 1013% The result shows that the horizontal ball mill able The design and optimization process of ball mill to reduce 2021年10月25日 Planetary ball mill is a powerful tool, which has been used for milling various materials for size reduction The discrete element method (DEM) was used to simulate the dynamics of particle (PDF) Simulation of a Laboratory Scale Ball Mill via

Ball Mill Design PDF Mill (Grinding) Atmosphere Of Earth

2017年12月10日 Volume at Mill Outlet 90 Degree = Celsius Air Flow Through mill (10 % margin =816211 NM3/Min Water Vapour due to evaporation of Mass/Volume Moisture = Of Water At 90 Degree Celsius 295633 M3 at 90 Degree Celsius Total Air Flow at the outlet of 680738 Mill = M3/ Hour at 90 degree celsius f) Consider 65 % to bag Filter = 44248 2016年11月18日 involve grinding) With Lloyd's ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone This article borrows from Lloyd's research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball millPage 1 Ball Milling Theory Free Shell2016年12月19日 Ð?( à?MB hp deskjet 3600 series 3600 se !@Üd ߀ ê o d , Bƒe‡ˆˆ ˆˆ R L d ÿÿÿÿ EXCEL ArialàààH Bƒe‡ ÌÚºÌÚº\\JSEPULVEDA\hp deskjet 3600 series,LocalOnly,DrvConvert Ë À r –*ì È X X ¡" d , , à? U } ¶ } $ } ¶ } $ ÿ ÿ ý F;ý '× D ìÚ ðD ð ð$ ð( ð ð ðŠ¢ ð à ðH€ÈcÚ ‚0e „0e ¿ ¿ À Ë Metallurgist Mineral Processing Engineer

A new methodology to obtain a corrected Bond ball mill

2022年10月1日 Based on the standard procedure defined by Bond, the ball mill work index is determined by simulating a closed cycle dry grinding in a laboratory Bond ball mill until a stable circulating load of 250% is established (Bond, 1949, Bond, 1952, Bond, 1961) The ball mill work index is determined by Eq (10) The recommendation is the ball mill 2016年10月31日 Pilot Plant Design; Process Design Optimization; Processing Services; Free Metallurgical Help 30, 25, and 20 mm balls (1 1/2, 1 1/4, 1 and 3/4 inch) is used for their ball mill work index DIY Ball Mill Plans Homemade Rod Mill Drawing1997年12月1日 From Equation 22 Qbond = 0007/0096 = 0m3/hr Calculate ~i full scale Input data: PBond = 008665 kW using Morrell power model for smooth mills (1992), PFull scale = 2456 kW, volumetric flowrate of the Bond mill QBond = 0 m3/h, volumetric flowrate of the full scale mill QFuU scale = 369m3/h Multiply ball size Using modelling and simulation for the design of full scale ball mill

(PDF) DYNAMIC ANALYSIS FOR BALL MILL FOUNDATION

2019年1月30日 The time history analysis is carried function is used for ha time step is 025 second for mill rotation and 00039 second for GMD motor m = 27 mils at top of mill pi litude calculated is 17 A Slice Mill is the same diameter as the production mill but shorter in length Request Price Quote Click to request a ball mill quote online or call 6303503012 to speak with an expert at Paul O Abbe® to help you determine which design and size ball mill would be best for your process See our Size Reduction OptionsVariables in Ball Mill Operation Paul O Abbe®Ball Mill Application and Design Ball mills are used the size reducing or milling of hard materials such as minerals, glass, advanced ceramics, metal oxides, solar cell and semiconductor materials, nutraceuticals and pharmaceuticals materials down to 1 micron or less The residence time in ball mills is long enough that all particles get Ball Mill Application and Design Paul O Abbe

Ball Mill Design/Power Calculation LinkedIn

2016年12月12日 If P is less than 80% passing 70 microns, power consumption will be Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work 2023年3月11日 Ball mill design handbook pdf This refers to a handbook in PDF format that provides guidance for designing, operating, and optimizing ball mills It includes information on mill sizing, mill power draw, grinding media charge calculation, and other important parameters that are essential for optimizing the mill’s operational conditionsball mill charge volume calculation marketreachcalculator2016年2月14日 Do you need a quick estimation of a ball mill’s capacity or a simple method to estimate how much can a ball mill of a given size (diameter/lenght) grind for tonnage a product P80 size? Use these 2 tables to get you close No BWi Bond Work Index required here BUT be aware it is only a crude approximation for “most soft ores” from F80 1 cm Small Ball Mill Capacity Sizing Table 911 Metallurgist

Ball Mill Critical Speed 911 Metallurgist

2015年6月19日 A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formula The mill speed is typically defined 2021年7月12日 Determining the Bond index using the Fred Bond method [1,2] is considered the stateoftheart methodology for mill calculations and a critical process parameter in raw materials selection and grinding A Review of Alternative Procedures to the Bond 2015年6月19日 We can calculate the steel charge volume of a ball or rod mill and express it as the % of the volume within the liners that is filled with grinding media While the mill is stopped, the charge volume can be Mill Steel Charge Volume Calculation 911

(PDF) DESIGN AND EVALUATE OF A SMALL

2015年12月18日 An H (m, g, k, 3) design is a triple (X, T, B), where X is a set of mg points, T a partition of X into M disjoint sets of size g, and B a set of kelement transverses of T, such that each 3 2016年3月25日 This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into fine powder and capable to work efficiently The cylindrical jar is used (PDF) DESIGN AND FABRICATION OF MINI BALL MILL2013年7月15日 b=70% b= 100% b=0% 2 E It should be emphasised that this increase is with respect to ~95% passing size material and not 80% passing size (or P80) as defined in Bond’s method screen sizes (PDF) Energy Efficient Ball Mill Circuit ResearchGate

Autogenous mills, semiautogenous mills and ball mills

2017年7月29日 3 The design offers such benefits as: xElimination of castings and the structural risk associated with them xFeed and discharge designed to process requirements rather than to restrictions imposed by trunnion bearings xMinimised risk of feed blockage through short trunnions xQuick accessibility to mill interior xLighter weight and lower 2023年3月22日 Jaw crusher, Ball mill, Burr mill and many others Thus, of all the crushing machines available, the Gyratory crusher, jaw crushers and the hammer mill are the most widely Design theories and Calculations Determination of Shaft Speed To calculate the shaft speed the following parameters are used 1 2 2 1 N N D D Spolt, 1988 (1) Where N 1DESIGN, FABRICATION AND TESTING OF A 2023年11月3日 to ball filling variation in the mill The results obtained from this work show, the ball filling percentage variation is between 12– 37% which is lower than mill ball filling percentage, according to the designed conditions (15%) In addition, acquired load samplings result for mill ball filling was 13%Method to Determine the Ball Filling, in Miduk Copper

Design, Construction and Performance Analysis of a 5

2017年8月4日 Since for the ball mill design we are using 80% passing, the required value of C2 for the ball mill will be equal to120 C3 is the correction factor for mill diameter and is given as; 𝐶𝐶3 = 244 𝐷𝐷 02 (3) However, it is important to note that C3 =0914 vessel used in producing the ball mill was got from a2021年2月4日 IV BALL MILLS Ball mills are one of the more common mills and use a closed cylindrical container that is rotated horizontally on its axis so that the media cascades A typical ball mill has an L/D ratio of 15:1 Ball mills are filled with spheres or other shapes made of steel or ceramics; or with pebbles made of flint (or of an ore being ATTRITORS AND BALL MILLS HOW THEY WORK Robert E 2023年10月19日 Ball Mill Calculations Free download as Excel Spreadsheet (xls), PDF File (pdf), Text File (txt) or view presentation slides online ball mill calculations Chimney Design Calc (1) Ball Mill Calculations PDF Mill (Grinding)

(PDF) DESIGN AND FABRICATION OF MINI BALL

2016年4月25日 To ensure the stability of the mini ball mill, a ball mill base is design and fabricate to withstand the weight of the rotating jar, motor and gears After a few hours, stop the mini ball mill and 2012年6月1日 ResearchGate Find and share researchResearchGate Find and share research2018年10月9日 1 Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the discrete element method, we must first be able to reproduce the balls’ motion in the ball mill using simulations Kano et al8) have made it clear that it is possible to reproduce the ball motion when the solid material isDesign Method of Ball Mill by Discrete Element Method

Design, Construction and Performance Analysis of a 5

Laboratory Ball Mill By C C Ugwuegbu, A I Ogbonna, U S Ikele, J U Anaele, U P Ochieze AOnwuegbuchulam Federal University of Technology Abstract In this study, a 5 kg laboratory ball mill has been designed, constructed, and its performance analysed This was achieved by using Bond’s equation to calculate the specific and2021年6月24日 35 Pebble Mill Design This reverts to the Morgärdshammar method and is similar to the AM calculation 36 Tower Mill The tower mill calculation is based on the ball mill design sheet, but is simplified in that the mill design section is omitted A simple tower mill factor of 70% allows the mill power to be estimated MILLCALCv2a 5 19/02/2004Grinding Mill Computer Model AusIMM2019年8月30日 V — Effective volume of ball mill, m3; G2 — Material less than 0074mm in product accounts for the percentage of total material, %; G1 — Material less than 0074mm in ore feeding accounts for 0074mm in the percentage of the total material, %; q’m — Unit productivity calculated according to the new generation grade (0074mm), t/(m3h) The Ball Mill Parameter Selection Calculation JXSC Machine

Ball Mill an overview ScienceDirect Topics

Quantum Nanostructures (QDs): An Overview D Sumanth Kumar, HM Mahesh, in Synthesis of Inorganic Nanomaterials, 2018 3611 Ball Milling A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball 2016年5月18日 Bag Filter Capacity = 41810064 M3/Hour At 70 Degree Celsius Taking 10 % Extra for Fan = 45991071 M3/Hour At 70 Degree Celsius Taking a Pressure drop of 150 200 mm of hg Hence bag filter fan =45991071 M3/Hour At Ball Mill Design PDF Mill (Grinding) Celsius Scribd2017年2月13日 CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′ High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volumeBall Mills 911 Metallurgist